Who We Are

Texin Technology

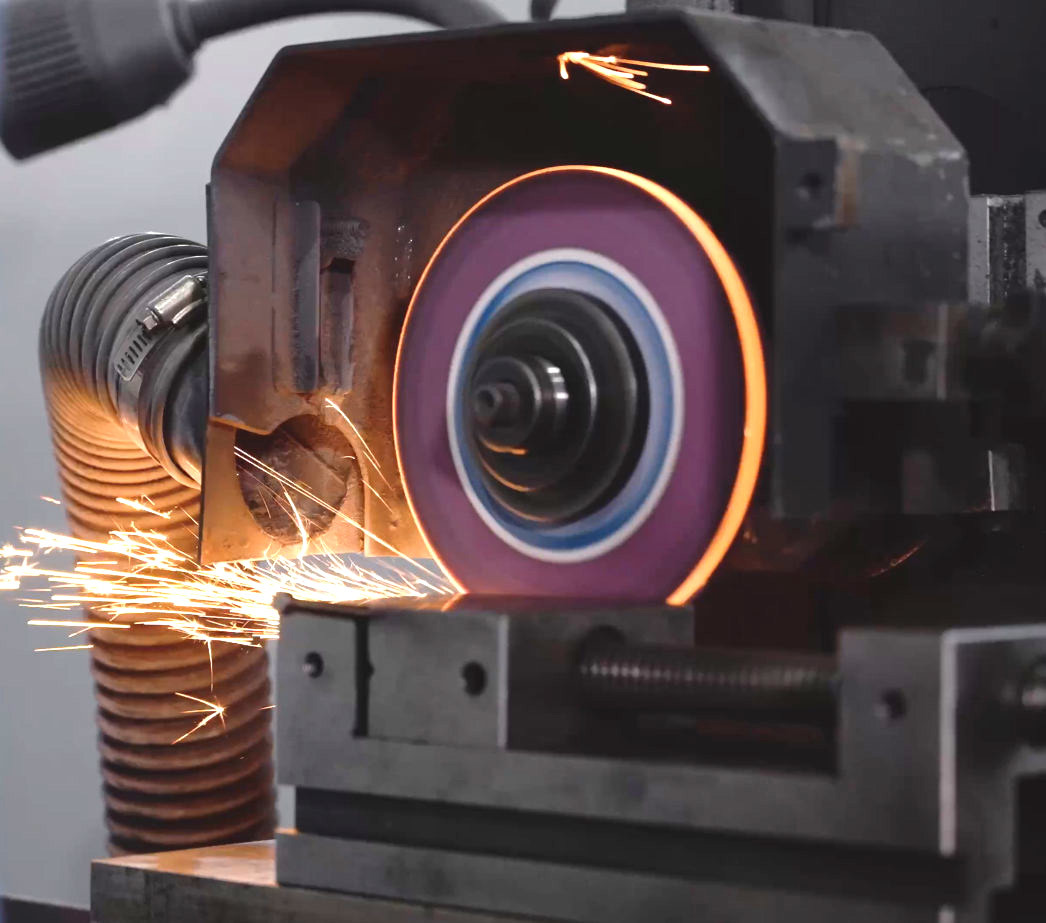

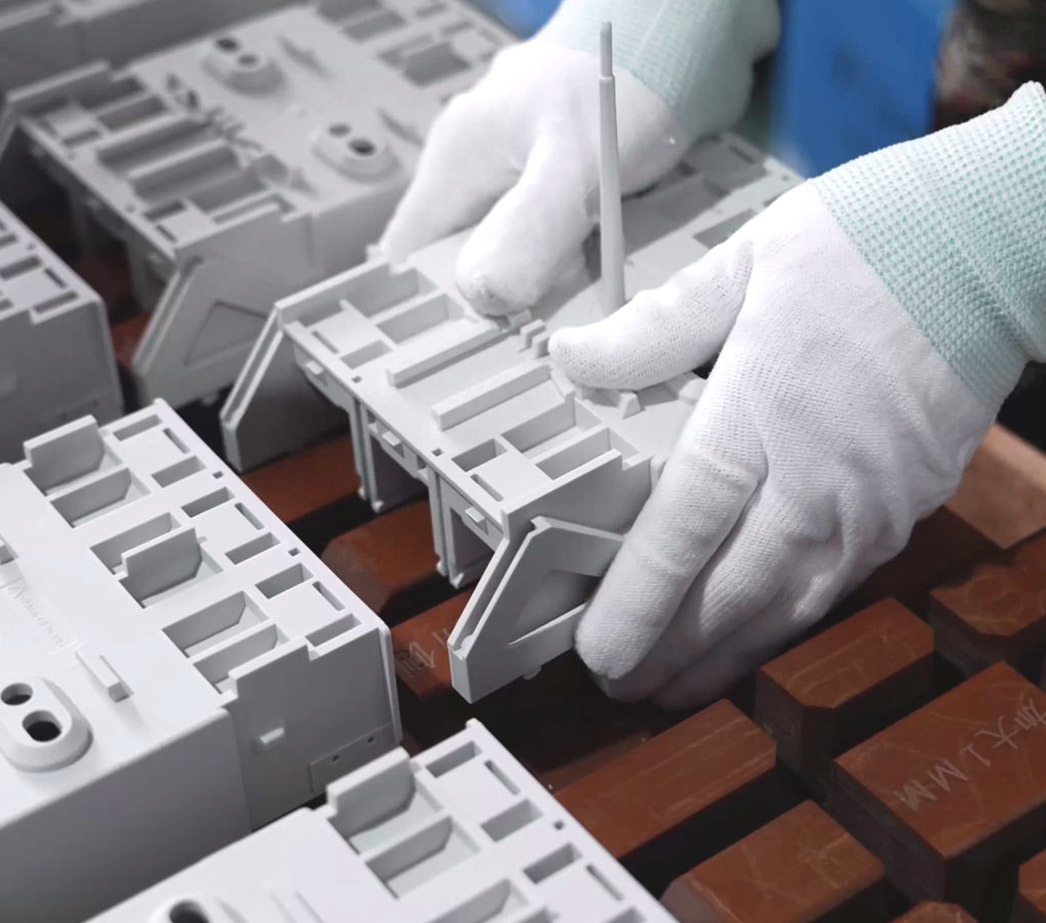

Texin (Xiamen) Technology Co., Ltd. specializes in the design and development, manufacturing and processing of plastic molds, aluminum alloy and zinc alloy molds, as well as injection molding supporting services. Products include electronic control products, electronic products, sanitary products, auto parts, sports equipment, medical, audio-visual and small home appliances and other precision molds and plastic products.

Since

Plant Area

Annual Mold Output

Partners

What We Do

Our Business

Products

Products Display

Cooperation

Our Partners

Blog

Latest Information

Jan 07,2025

Professional manufacturer of aluminum alloy and zinc alloy molds

Products include electronic control products, electronic products, sanitary products, auto parts, sports equipment, medical, audio-visual and small home appliances and other precision molds and plastic products.

Mar 06,2026

The Significance of Precision Mold Parts in Plastic Injection Molding

Precision mold parts play a vital role in the manufacturing process of plastic injection molding, which is a technique widely used in the production of plastic components across various industries. These precision-engineered components are essential for ensuring that the final products meet the highest standards of quality, accuracy, and consistency. Understanding the significance of precision mol

Mar 05,2026

Injection Molded Parts for Household Medical Housing

Injection molded parts for household medical housing are precision plastic components used in medical devices. They provide strong durability, impact resistance, and smooth surface finish, ensuring safe and reliable protection for home medical equipment.

Mar 03,2026

Unlocking Efficiency: The Role of Precision Mold Parts in Modern Manufacturing

Unlocking Efficiency: The Role of Precision Mold Parts in Modern Manufacturing Manufacturers today are constantly seeking ways to improve efficiency, reduce costs, and maintain high-quality standards. At the heart of this quest lies the **importance of precision mold parts**. These components play a crucial role in the production process, directly impacting the overall quality of manufactured good

Service

TEXIN Solutions

Tell us your needs, Texin Technology will serve you wholeheartedly.