Texin — Injection Molded Sports Equipment built to perform

Texin is committed to providing customers with quality products and services

Classification:

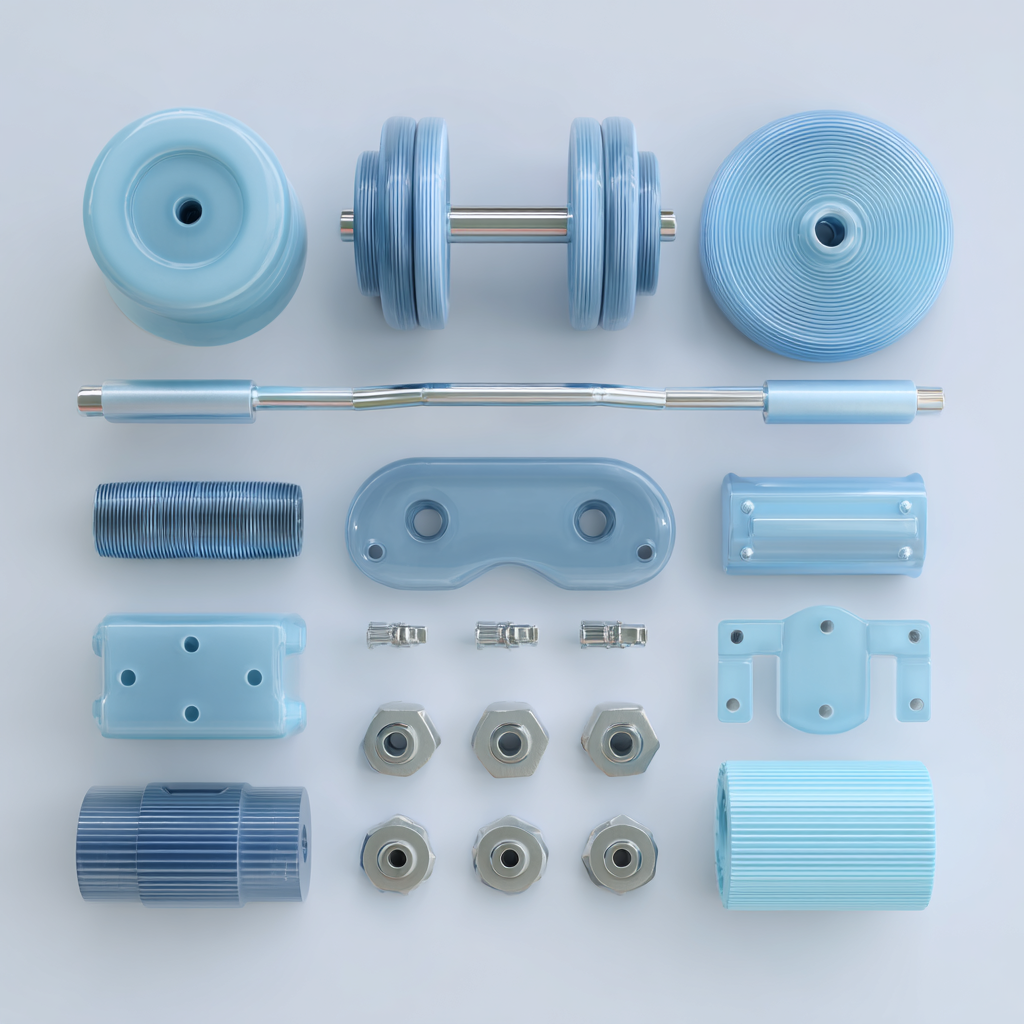

Injection Molded Sports Equipment

Key words:

Get Quote

Intro:

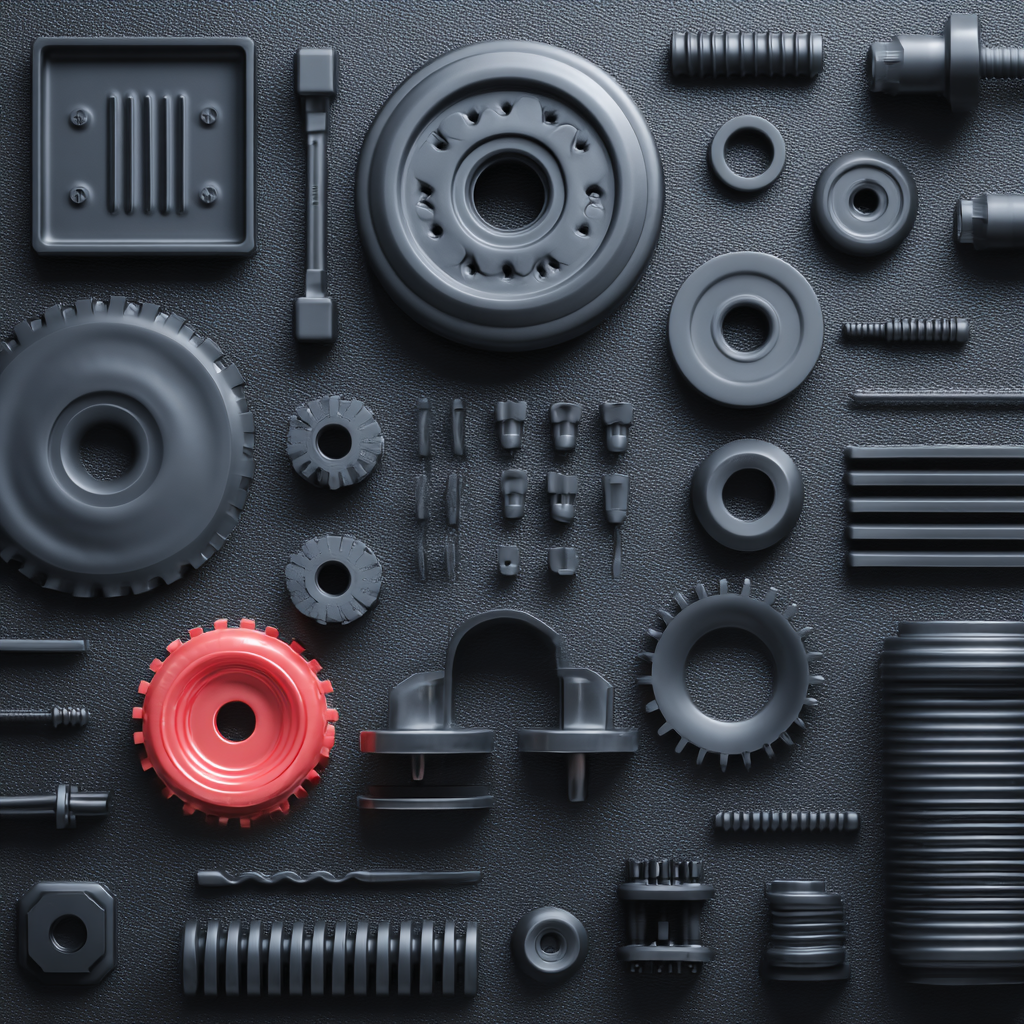

Sports gear and facility components are punished in real use: sun, rain, repeated impacts, sliding abrasion and heavy foot traffic. Injection Molded Sports Equipment must combine the right polymer or composite, thoughtful part design and tight process control. At Texin we manufacture parts that last — from molded housings and bench fittings to track wear layers and turf connectors — by matching materials (PVC, PP, PE, PU, PC, nylon, polyester and fiber‑reinforced laminates) to the job and validating with real tests.

Why the bar is high Buyers don’t accept cosmetics alone. A part must:

- Hold dimensional tolerance after repeated load cycles. We commonly target ±0.1 mm for general features and can reach ~±0.05 mm for precision details with proper tooling and process control.

- Resist UV, moisture and oxidation for outdoor life — PVC/PP/HDPE grades with UV stabilizers are typical choices.

- Absorb energy where needed — PU and PE are standard for shock‑absorbing track surfaces and turf systems.

- Withstand impacts and wear — PC, nylon and glass‑filled polymers are used for backboards, housings and sliding components.

Meeting those needs means materials engineering plus tooling, mold cooling, gate design and QC.

What Texin brings

- Material selection: We specify PVC/PP/PE for fixtures, PU/PE for cushioning surfaces, PC/nylon for impact parts, and carbon/glass fiber laminates with epoxy/polyester resin for structural blades.

- Process capability: injection molding for complex repeatable parts, extrusion for profiles, and lamination/composite layup for high‑stiffness pieces. Insert molding and overmolding (TPE on hard substrates) are standard.

- Durability validation: We use accelerated weathering (QUV/Xenon), mechanical tests (impact, tensile, abrasion) and surface checks to confirm long life.

- Practical production know‑how: balanced flow, controlled cooling, and optimized packing to reduce warpage, sink marks and short shots.

Targeted buyer & maker questions — direct answers

Which material for an outdoor bollard, bracket or bench part?

Use HDPE or PP with UV stabilizers for long weatherability and abrasion resistance (PVC is also an option for some fixtures).

Running track or artificial turf — what do I choose?

Tracks and turf surfaces commonly use PU and PE. PU provides superior shock absorption and anti‑slip feel; PE is widely used for turf yarn. Artificial turf systems combine grass yarn (PE/PP), backing and infill (SBR/EPDM rubber or sand) to hit play and safety targets.

What polymer resists repeated impacts best?

Polycarbonate (PC) and engineering nylons (optionally glass‑filled) give the toughness needed for backboards and housings exposed to repeated hits.

When are composites the right solution?

When stiffness‑to‑weight is critical — skis, performance blades and some frames — use carbon or glass fiber laminates with epoxy or polyester matrices for lightweight strength.

How tight are realistic injection‑molding tolerances?

Typical production parts: ±0.1 mm. Precision features with stable geometry, good tooling and process control: around ±0.05 mm.

What common molding defects occur and how do you fix them?

- Short shot: improve melt pressure/venting or gate size.

- Warpage: balance wall thickness, adjust gate locations and cooling.

- Sink marks: increase packing or redesign wall sections.

Temperature, pressure and cycle time control are the core levers.

How do you assure outdoor longevity?

Choose weathering‑grade PE/PP/HDPE, add UV stabilizers/antioxidants, and validate with accelerated QUV/Xenon tests to project service life.

Can you make multi‑material or assembly parts?

Yes — overmolding (TPE grips), insert molding (metal fittings), and composite lamination are standard solutions at Texin.

What tests should I ask for?

Request impact resistance, tensile/elongation, Shore hardness, abrasion resistance and UV aging. For turf/track systems, sports‑specific metrics (shock absorption, Gmax) should be included.

Are these materials recyclable?

Many are: PE and PP are broadly recyclable; some PC grades also. Biodegradable blends exist but may trade off heat resistance or mechanical performance.

Do you support certifications and standards?

We design to meet customer market requirements — common references include EN/ISO/ASTM for mechanical and fire performance, plus REACH/RoHS for restricted substances. Tell us target markets (EU, US, Japan, etc.) and we’ll match requirements.

Concrete examples (what we typically deliver)

- Injection molded turf clips and connectors in HDPE/PP with UV package.

- Overmolded hand grips (TPE over glass‑filled nylon) for gym equipment.

- PU wear layers for running track segments with textured anti‑slip surfaces.

- Polycarbonate molded backboards and impact housings for outdoor courts.

- Composite ski cores and blades using carbon/glass layups and epoxy.

Summary — short and practical Injection Molded Sports Equipment requires material know‑how, careful design and disciplined manufacturing. Texin combines polymer selection (PVC, PP, PE, PU, PC, nylon and composites), injection molding and composite capabilities, plus durability testing (QUV/Xenon and mechanical testing), to deliver parts that perform where it matters. If you can share your performance targets — tolerance, impact energy, expected outdoor life, or sports‑specific metrics (e.g., shock absorption or Gmax for turf) — we’ll provide a tailored material recommendation, manufacturability review and sampling plan.

Contact Texin to begin: tell us the part, target environment and any standards you must meet, and we’ll respond with material options, expected tolerances and a pilot plan for your Injection Molded Sports Equipment.

● Many years of mold design, development and manufacturing experience

● Pursue excellence and cast high quality

● High quality, high efficiency and high precision

● Take the initiative to provide timely, fast and dynamic customer service

A simple 3-step process for quickly obtaining a commercial offer

Step 1: Leave your details and our technical specialists will contact you within 24 hours.

Step 2: Confirm the materials for the production process and technical specifications.

Step 3: Get the commercial offer and the lead time.