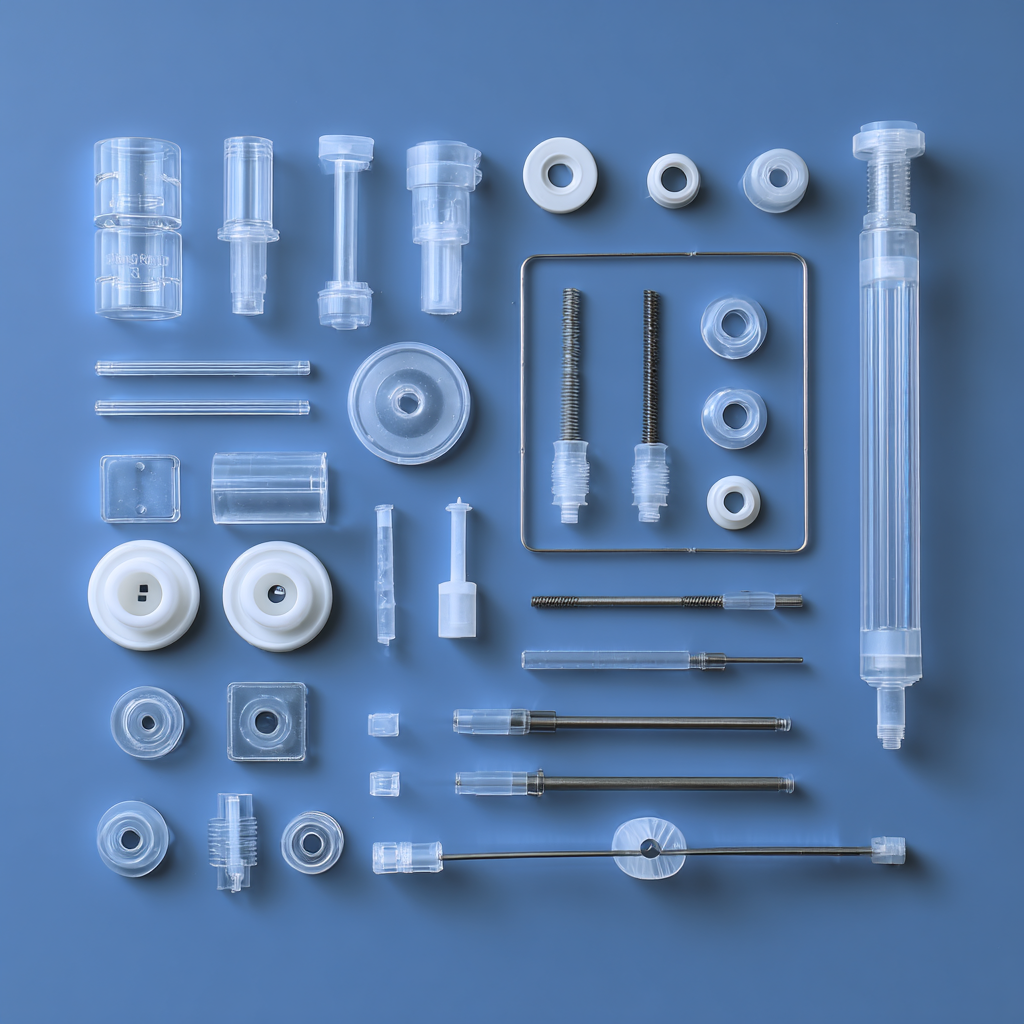

Texin — Precision Injection Molded Medical Catheter Plastic Parts

Texin is committed to providing customers with quality products and services

Texin provides precision injection‑molded medical catheter plastic parts using medical‑grade materials (PVC/PE/PP/PC/TPU), hardened mold steels (S136/H13) and validated scientific injection molding. We ensure sterilization compatibility (EO/gamma/steam), strict incoming inspection, SPC control and full batch traceability.

Classification:

Medical injection molding products

Key words:

Get Quote

Introduction Medical catheter plastic parts demand exceptional precision, biocompatibility and process control. At Texin we specialize in injection molded Medical catheter plastic parts—producing hubs, connectors, adaptors and small structural components with controlled dimensions, clean manufacturing and documentation needed by medical device makers. These parts must meet tight dimensional tolerances, sterilization compatibility and traceability; our tooling, materials expertise and “scientific injection molding” workflow are built to deliver.

Why Medical catheter plastic parts require extra care

- Material choice and biocompatibility: Catheter parts contact fluids and sometimes patient tissue. We work with medical-grade materials commonly used in the industry (PVC, PE, PP, TPU, POM, PC, PTFE for special seals). Note: PVC accounts for >25% of medical plastic use and PE ~24%; PP ~16% — these figures reflect market prevalence and material suitability for disposable or flexible parts.

- Long-run, high-precision tooling: For stability and surface quality (critical for hubs and luer fittings) we recommend Grade 1–2 molds (Grade 1 ≥1,000,000 cycles; Grade 2 ≈500k–1,000k cycles) manufactured in hardened steels such as S136, H13 or 420 to allow mirror finishes and long life.

- Validated process & traceability: We lock process recipes from trial through pilot runs, record shot weight, mold temps and pack curves, and maintain batch traceability (resin lot, mold ID, production date) for every Medical catheter plastic parts order.

- Contamination & moisture control: Hygroscopic resins (e.g., PA) and moisture-sensitive defects are prevented by controlled drying per T/T, closed conveying and incoming moisture checks.

Common buyer / producer questions — concise answers

Q1 — What materials are best for catheter hubs, connectors and fittings?

A1 — Typical choices: PP or HDPE for disposable rigid parts (chemical resistance, radiation tolerance); POM or PC for precision fittings needing stiffness/clarity; TPU or TPE for flexible seals; PVC used extensively for flexible tubing (note PVC >25% of medical plastics). For implantable or high-temperature needs consider PPSU / PEEK.

Q2 — Which mold grade and steel should I request?

A2 — For high-volume Medical catheter plastic parts choose Grade 1 (≥1,000,000 cycles) or Grade 2 (≈500k–1,000k cycles) using corrosion‑resistant steels such as S136, 420 or H13 (HRC48–52). Mirror polishing is advised for sealing surfaces and transparent components.

Q3 — How do you prevent shrinkage, sink or warpage?

A3 — We start with Moldflow and material datasheets → set initial barrel/mold temps and injection profile → run “scientific injection molding” trials while recording fill/pack curves → adjust gate size/location and cooling circuits as needed → lock parameters and apply SPC. In cases where shrinkage occurs at remote areas we often enlarge the gate and optimize cooling balance.

Q4 — How to distinguish moisture-related streaks from poor plasticization?

A4 — Dry a resin sample per recommended T/T and run a trial: if streaks disappear, moisture was the cause. If not, review screw size/residence and plasticating capacity—PC with under‑sized screw can show “flow lines” indistinguishable from wet resin defects.

Q5 — What incoming checks and documentation do you provide?

A5 — Incoming checks: COA review, visual color check, MFI, density and moisture for hygroscopic resins. Deliverables: trial report, locked process card (barrel zones, mold temp, injection/pack profile), Moldflow summary and batch traceability data. Third‑party testing (SGS/Eurofins) can be arranged on request.

Q6 — Sterilization compatibility — what to consider?

A6 — PP/HDPE: gamma radiation friendly (common for disposables). PC: steam autoclave tolerant (when clarity & autoclave resistance required). For high‑temperature or implantable use: PPSU or PEEK. We provide sterilization compatibility statements and can test parts post‑EO/gamma/steam.

Production controls and packaging

- Cooling fluid control: We monitor and control cooling fluid temperature before entry to the mold (sensors + PID) to avoid mold temp drift that causes dimensional variation.

- FMEA & moisture management: High-absorption materials (nylon/PA) are addressed in FMEA with drying, sealed storage and in‑line drying on the production line.

- Packaging: sterile or clean packaging options, batch labels including resin lot, mold ID and sterilization batch number are available.

Summary:

Medical catheter plastic parts require exacting materials, long‑life tooling (Grade 1–2 molds like S136/H13), validated “scientific injection molding,” strict incoming inspection and sterilization-aware design. Texin combines material expertise, hardened tooling, controlled processes and full batch traceability to deliver reliable Medical catheter plastic parts for regulated supply chains. Contact Texin for a DFM review, sample validation or quote for your Medical catheter plastic parts project.

● Many years of mold design, development and manufacturing experience

● Pursue excellence and cast high quality

● High quality, high efficiency and high precision

● Take the initiative to provide timely, fast and dynamic customer service

A simple 3-step process for quickly obtaining a commercial offer

Step 1: Leave your details and our technical specialists will contact you within 24 hours.

Step 2: Confirm the materials for the production process and technical specifications.

Step 3: Get the commercial offer and the lead time.

Previous Page