Texin — Durable Fitness Equipment Injection Molds Built for Strength and Safety

Texin is committed to providing customers with quality products and services

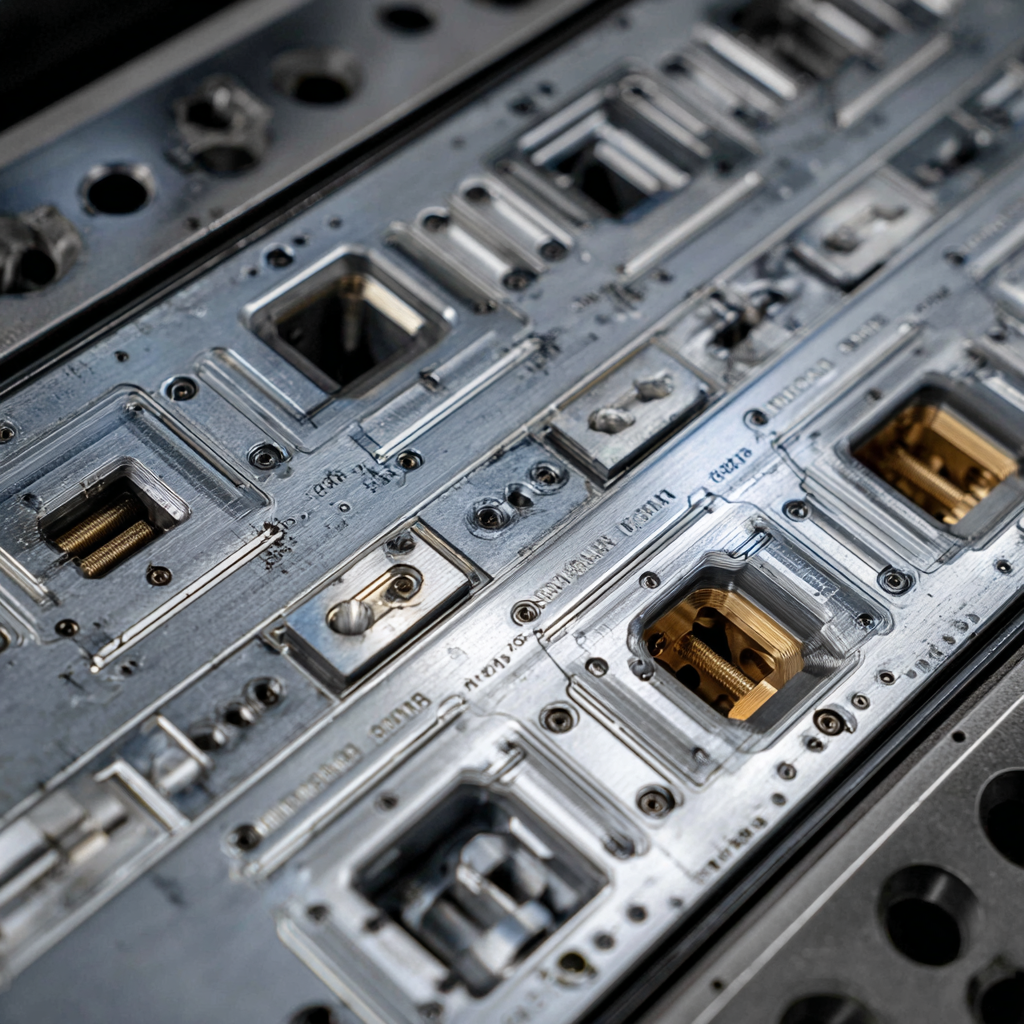

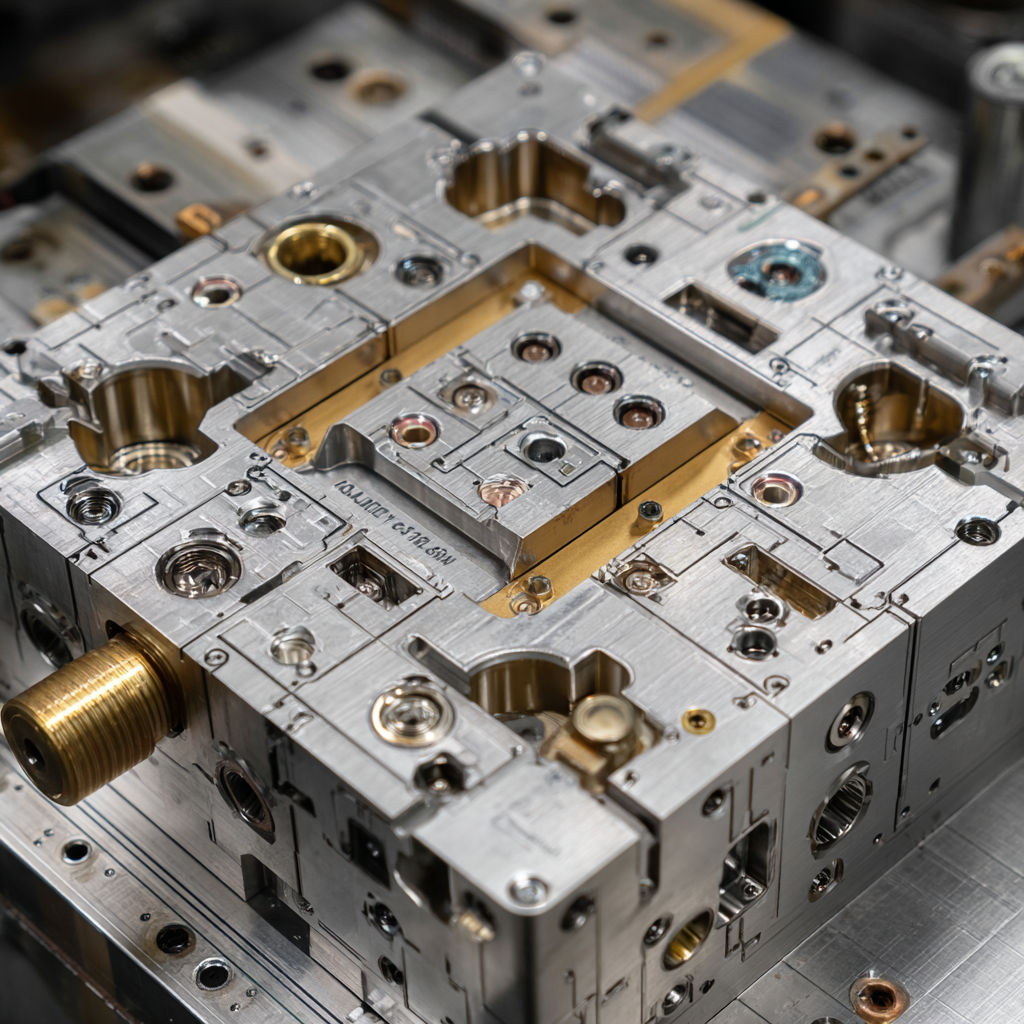

Texin produces fitness equipment injection molds for high‑load parts (handles, housings, grips). We provide full DFM → design → material sourcing → precision CNC/EDM machining → assembly → trial runs, using steels 45#, 718H, S136, NAK80. Typical timelines: feasibility 1–3 days, design 3–7 days; machining often 40–60% of lead time. We offer CMM inspection, mirror/textured finishes, warranty and spare‑parts support to ensure reliable, high‑volume production.

Classification:

Mold parts

Key words:

Get Quote

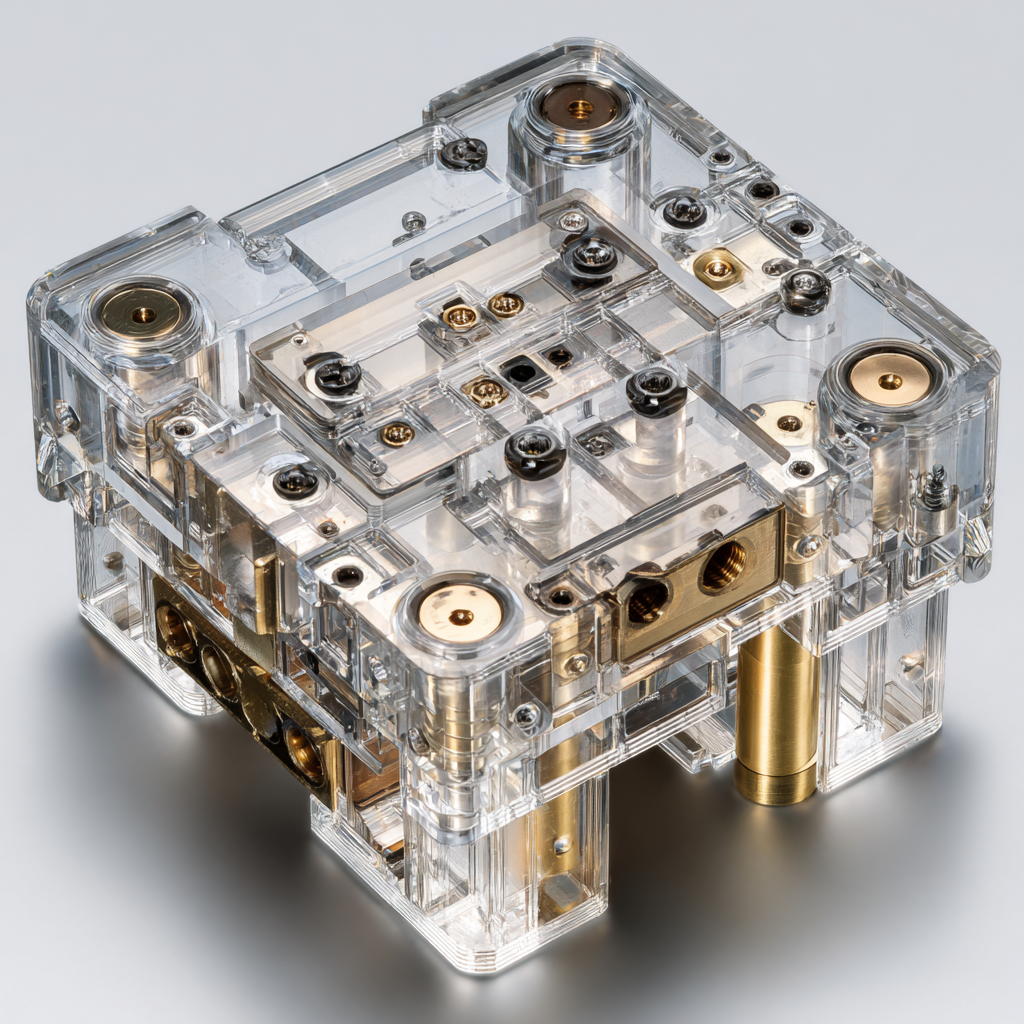

At Texin we design and build fitness equipment injection molds for parts that must withstand heavy use, strict safety requirements and repeated mechanical stress. From kettlebell handles, exercise bike housings and pedal components to adjustable clamp parts, grips and protective covers, fitness parts require strong materials, consistent wall thickness, tight tolerances and long tool life. Our fitness equipment injection molds are engineered to deliver rugged, repeatable parts for high-volume production.

Why fitness equipment injection molds demand special care

- Mechanical load and fatigue: Fitness parts often bear repeated loads and impact — the mold must produce parts with uniform wall thickness and correct rib/support geometry to avoid stress concentrations.

- Material compatibility: Many components use engineering plastics (PA, PA+GF, POM, PC, ABS+PC) or flame-retardant grades; mold steel and surface finish choices affect part performance.

- Surface and grip: Ergonomic grips or textured surfaces require repeatable texture engraving or fine polishing for comfort and wear resistance.

- Long production life: Fitness products can be mass-produced; molds must keep dimensions stable over thousands to millions of cycles.

What Texin delivers for fitness equipment programs

- End-to-end workflow: feasibility → mold design → material procurement → precision CNC/EDM machining → assembly & debug → trial & optimization. These six stages minimize surprises and speed ramp-up to production.

- Fast feasibility checks: initial DFM review usually 1–3 days to flag wall thickness, undercuts or draft issues and propose fixes.

- Practical design turnaround: standard mold design 3–7 days (complex multi-slide or multi-cavity tools may take longer).

- Material & steel choices: we work with 45# (prototypes/low volume), 718H (pre-hardened for medium runs), S136 (mirror-grade for polished decorative surfaces), NAK80 (age-hardening for fine cavities without heavy heat treatment). Domestic steel typically 1–3 days; imported mirror steels 1–4 weeks. Material cost commonly represents ~20–30% of mold cost.

- Precision machining & finishing: CNC provides micron-level geometry; EDM/WEDM and polishing handle tight radii, contact surfaces and mirror/textured finishes. Machining and processing often account for 40–60% of lead time and 30–50% of mold cost.

- Trial & validation: trial molding validates function and assembly (1–3 days per trial). For complex parts 2–3 iterative trials are common.

Typical buyer / producer questions — concise answers (data-backed)

Q: What files do you need to start? A: Provide a 3D model (STEP/IGES/Parasolid) + 2D drawings with key dims, material spec (e.g., PA66 GF30, POM, PC+ABS), surface finish, and expected annual volume. This enables a 1–3 day feasibility review.

Q: Which steels are recommended for fitness molds? A: For prototypes: 45#. For production with moderate life: 718H. For polished or corrosion-resistant finishes (decorative bezels, glossy housings): S136. For high-precision cavities where heat treatment is undesirable: NAK80.

Q: How long from drawings to first trial parts? A: Typical schedule:

- Feasibility 1–3 days

- Mold design 3–7 days

- Machining & assembly: for medium complexity expect 2–4 weeks (machining often 40–60% of lead time)

- Trial/validation: 1–3 days per trial

Total: standard molds in a few weeks; complex fitness molds may take longer.

Q: What tolerances and inspection can you achieve? A: For critical features we can target tight tolerances (typical critical-feature range ±0.01–0.005 mm when specified). We perform multi-stage inspection including CMM, visual checks and first-article reports during trials.

Q: Can you produce textured grips or mirror finishes? A: Yes. Textures are engraved/laser-etched and replicated via cavity textures; mirror finishes are achieved by S136-type steel plus polishing and fine EDM.

Q: What does a trial run include and what are typical costs? A: Trial includes mold installation, test shots, dimensional & visual checks and initial adjustments. A single trial usually takes 1–3 days; costs vary with press time and adjustments (single-trial costs can range from several thousand depending on scope).

Design and production tips we apply for fitness parts

- Keep wall thickness uniform around load-bearing zones to avoid sink, warp and stress concentration.

- Define critical assembly dimensions and tolerances up front (snap-fit engagement, bearing housings, shaft fits).

- Use ribs and fillets to strengthen structures but avoid abrupt thickness changes.

- If undercuts are needed for locking features, plan slides or lifters and specify required stroke and life.

Why choose Texin for fitness equipment injection molds

- Focused experience: we understand load-bearing design needs for fitness parts and choose steels and finishes accordingly.

- Transparent costing & scheduling: material commonly 20–30% of mold cost; machining and processing typically 30–50%. Machining is the major time driver (40–60% of lead time).

- Practical validation: structured trial runs (1–3 days each) and multi-stage inspection (CMM, FAR) reduce start-up risk.

Summary:

Fitness equipment injection molds require a mix of mechanical robustness, precise tolerances and consistent surface/textures. Texin combines practical DFM, correct steel selection (45#, 718H, S136, NAK80), micron-level CNC/EDM machining and staged trial validation to deliver reliable fitness equipment injection molds that perform under repeated load and in high-volume production. Send us your 3D files, 2D key dims, material spec and expected volume — Texin will return a feasibility review, timeline and tailored plan to take your fitness part into consistent production.

Ready to discuss? Contact Texin for a feasibility review on your fitness equipment injection molds project.

● Many years of mold design, development and manufacturing experience

● Pursue excellence and cast high quality

● High quality, high efficiency and high precision

● Take the initiative to provide timely, fast and dynamic customer service

A simple 3-step process for quickly obtaining a commercial offer

Step 1: Leave your details and our technical specialists will contact you within 24 hours.

Step 2: Confirm the materials for the production process and technical specifications.

Step 3: Get the commercial offer and the lead time.