Why Injection Molded Catheter Parts Matter for Everyone

Release time:

Sep 20,2025

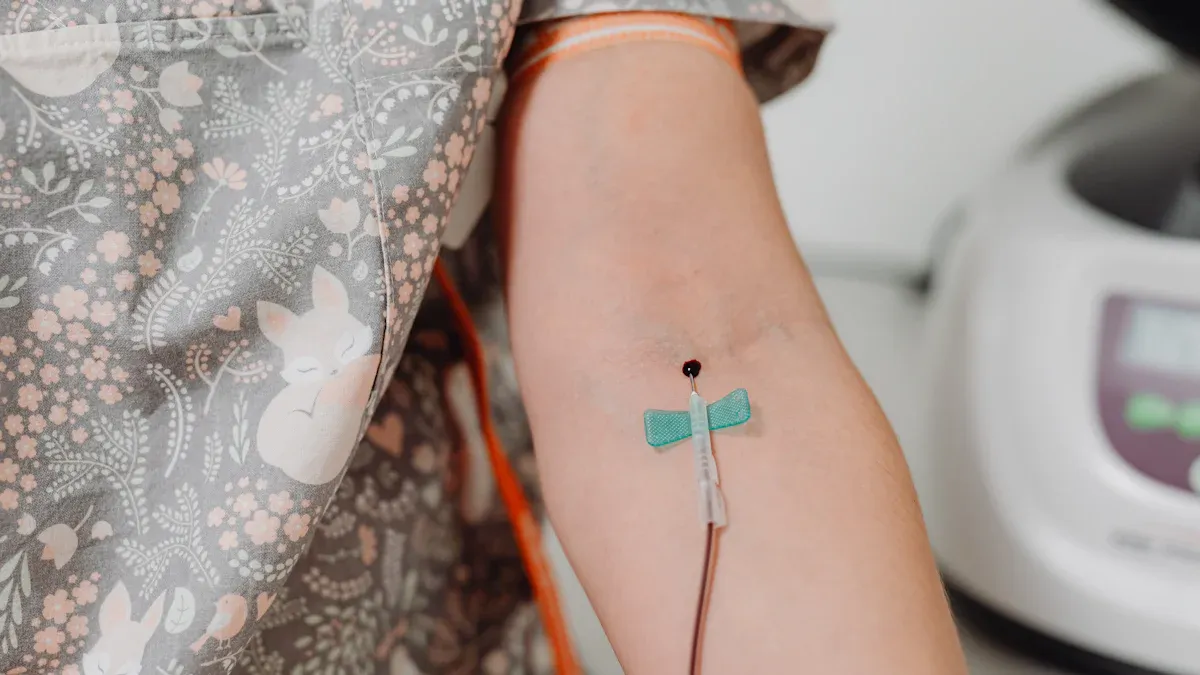

You depend on safe, reliable medical devices every day, even if you never notice them. Small components, such as injection molded catheter parts, play a crucial role in protecting patient safety and improving healthcare outcomes. These hidden details support your trust in hospitals and clinics. When you see a loved one receive care, you can feel confident that the quality of these parts safeguards their wellbeing.

Key Takeaways

- Injection molded catheter parts are essential for patient safety. Reliable components prevent discomfort and serious harm during medical procedures.

- Manufacturers use strict quality checks to ensure that every catheter part meets high medical standards. This attention to detail leads to better healthcare outcomes.

- Injection moulding allows for precise and consistent production of catheter parts. This process ensures that each component fits perfectly and functions reliably.

- Full batch traceability guarantees that every part can be tracked from raw material to finished product. This system enhances safety and compliance in medical device manufacturing.

- Choosing high-quality injection molded parts supports effective healthcare. Trust in the unseen work behind these components ensures better care for you and your loved ones.

Why Reliability Matters

Patient Safety

You trust medical devices to keep you safe. When you receive treatment, you expect every part to work as intended. Patient safety depends on the reliability of each component, especially in devices like catheters. If a catheter part fails, it can cause discomfort, infection, or even serious harm. You rely on the reliability of these parts to protect your health during procedures.

Manufacturers focus on patient safety by using strict quality checks. They select materials that meet medical standards. You benefit from this attention to detail every time you or a loved one needs care. Reliability in catheter parts means fewer risks and better outcomes for everyone.

Reliable Medical Device Performance

You expect reliable medical device performance in every hospital or clinic. Devices must function correctly, even under pressure. Reliability ensures that catheters deliver fluids, medications, or drainage without interruption. When you use a device with reliable medical device performance, you avoid delays and complications.

- Reliable medical device performance means:

- Consistent operation in every use

- No unexpected breakdowns

- Smooth interaction with other medical equipment

Reliability also supports healthcare professionals. When devices perform reliably, doctors and nurses can focus on your care, not on fixing equipment. You gain peace of mind knowing that reliable medical device performance is a top priority in modern healthcare.

Reliability is not just a technical term. It is the foundation of patient safety and reliable medical device performance. You deserve nothing less.

Injection Molded Catheter Parts

What Is Injection Moulding?

You may wonder how manufacturers create precise medical components. Injection moulding is a process that shapes plastic by forcing molten material into a mould. You see this method used in many industries, but it is especially important in healthcare. Injection moulding allows you to get complex shapes with high accuracy. You benefit from this process because it produces consistent, reliable parts every time.

You find injection moulding in the production of catheter parts because it offers excellent control over dimensions. You can trust that each part will fit perfectly with other medical devices. Injection moulding also supports the use of medical-grade plastics, which are safe for patient contact.

Key Features

You want catheter parts that meet strict standards. Injection moulding gives you this reliability. Texin uses only high-quality medical-grade materials such as PVC, PE, PP, PC, and TPU. You get parts that are strong, flexible, and safe for use in medical settings.

You benefit from Texin’s rigorous production processes. The company uses hardened mould steels like S136 and H13, which ensure long-lasting precision. You can rely on these parts to withstand sterilisation methods, including ethylene oxide, gamma radiation, and steam. Injection moulding makes it possible to produce a wide range of parts, such as hubs, connectors, adaptors, and other small components.

You also gain peace of mind from full batch traceability. Texin tracks every step, from raw materials to finished product. You know that each injection molded part meets strict quality standards. Injection moulding ensures you receive safe, reliable components for every medical procedure.

Reliability and Safety in Catheter Parts

Consistency and Durability

You expect catheter parts to perform reliably every time. Consistency in manufacturing means you receive the same high standard with each part. Texin achieves consistent part quality by using high-quality materials and advanced injection moulding techniques. You benefit from components that do not change shape or lose strength during use.

Durability matters for safety. You want parts that withstand repeated sterilisation and handling. Texin selects materials such as PVC, PE, PP, PC, and TPU for their strength and resistance to wear. You see the results in parts that remain safe and effective throughout their lifespan.

Design for reliability guides every step. Texin engineers each part to meet strict standards. You trust that every hub, connector, or adaptor will work as intended, even in demanding medical environments.

Quality Control

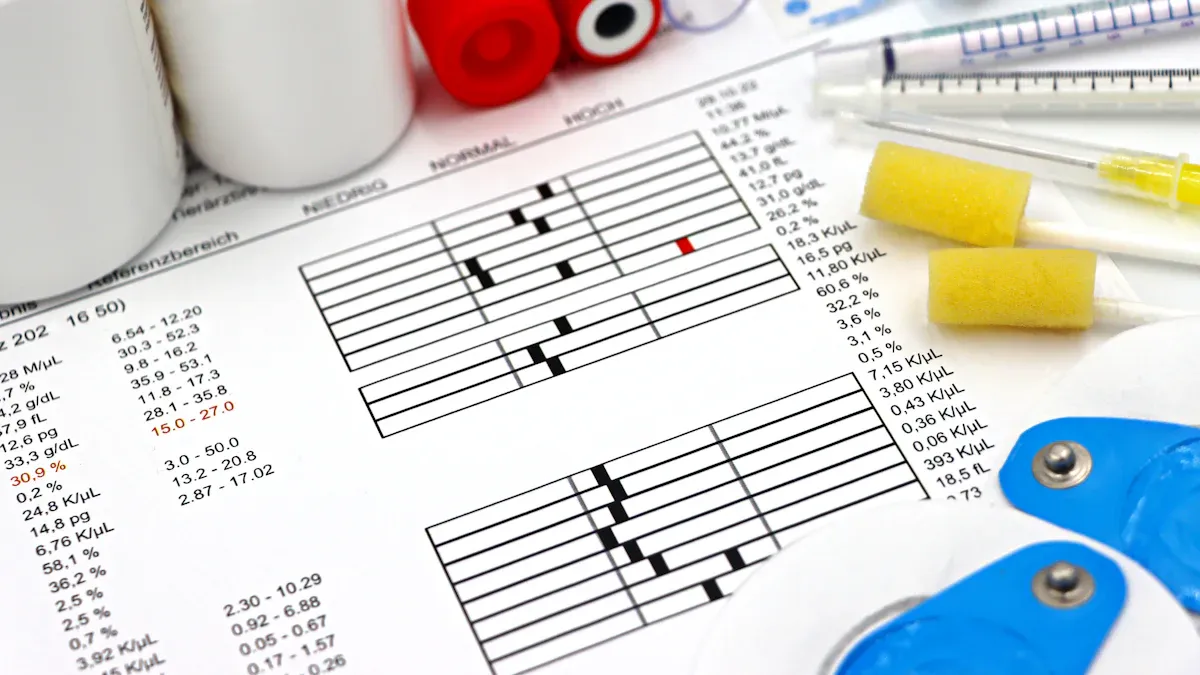

You rely on rigorous testing to ensure safety. Texin implements strict quality control at every stage. Incoming inspections check raw materials for purity and suitability. Moisture management prevents defects and maintains the integrity of high-quality materials.

Testing continues throughout production. You see the benefits in parts that pass multiple checks for dimensions, strength, and compatibility. Rigorous testing ensures that only safe components reach you.

Full batch traceability supports safety and compliance. You can track each part from raw material to finished product. Detailed records help you confirm that every item meets medical standards. This traceability protects you if any issue arises, allowing quick identification and resolution.

Packaging plays a vital role in safety. Texin uses sterile packaging with clear batch labelling. You find information such as resin lot numbers and sterilisation batch details on every package. This attention to detail ensures you receive safe, uncontaminated parts.

You benefit from a process that prioritises safety at every step. Quality control, batch traceability, and sterile packaging work together to protect you and support healthcare professionals.

- Key steps in Texin’s safety process:

- Incoming inspections of high-quality materials

- Moisture management during production

- Rigorous testing for dimensions and strength

- Full batch traceability for compliance

- Sterile packaging with detailed labelling

Note: You can request documentation for any batch to confirm safety and quality standards.

Injection Moulding vs Other Methods

Advantages of Injection Moulding

You see many ways to make catheter parts, but injection moulding stands out in medical device manufacturing. This method gives you unmatched precision and high dimensional accuracy. You get parts that fit perfectly every time. Traditional methods, such as machining or casting, often struggle to deliver the same level of consistency in design and production.

Injection moulding supports high-volume production. You benefit from faster turnaround and lower costs per device. This process allows you to use biocompatible materials, which are essential for medical safety. You can trust that each device meets strict standards for medical device development.

You also gain flexibility in design. Injection moulding lets you create complex shapes and fine details. You can optimise material selection for each application, which is vital for drug delivery systems and other advanced medical devices. Texin’s expertise in material optimisation ensures you get the best results for your device design and production needs.

- Key benefits of injection moulding in medical device manufacturing:

- Precision and high dimensional accuracy

- Consistent quality in high-volume production

- Wide choice of biocompatible materials

- Flexible design options for medical device development

Impact on Safety

You want every medical device to be safe and reliable. Injection moulding helps you achieve this goal. The process ensures that each part meets strict design and production standards. You can monitor performance and detect any issues early through batch traceability and detailed monitoring.

Injection moulding supports the use of materials that resist contamination and withstand repeated sterilisation. You see improved safety in drug delivery systems and other critical medical applications. Texin’s focus on design, production, and maintenance means you receive parts that support safe device operation and easy maintenance.

You can rely on injection moulding for medical device manufacturing because it delivers consistent performance, supports ongoing monitoring, and simplifies maintenance. This approach gives you peace of mind in every stage of medical device development, from design to production and maintenance.

Reliable injection moulded catheter parts keep you safe and support effective healthcare. You benefit from quality, precision, and full traceability in every component. When you choose medical devices, you support high standards and trust in the unseen work behind each part. For more information or to ensure quality, reach out to trusted manufacturers.

FAQ

What materials do you use for injection moulded catheter parts?

You find medical-grade PVC, PE, PP, PC, and TPU in these parts. Each material offers unique benefits for strength, flexibility, and safety. You can trust these materials for direct patient contact.

How do you ensure the quality of each catheter part?

You benefit from strict quality control. Technicians inspect raw materials, monitor production, and test finished parts. You receive only components that meet high standards for safety and performance.

Are injection moulded catheter parts safe for sterilisation?

You can safely sterilise these parts using ethylene oxide, gamma radiation, or steam. The materials and design withstand repeated sterilisation cycles without losing strength or shape.

What types of catheter parts can you produce with injection moulding?

You see hubs, connectors, adaptors, and many small components made by injection moulding. This process allows you to create complex shapes with precise dimensions.

Why is batch traceability important in medical device manufacturing?

You rely on batch traceability to track every part from raw material to finished product. This system helps you confirm safety, resolve issues quickly, and meet strict medical regulations.

Related Blog

Share