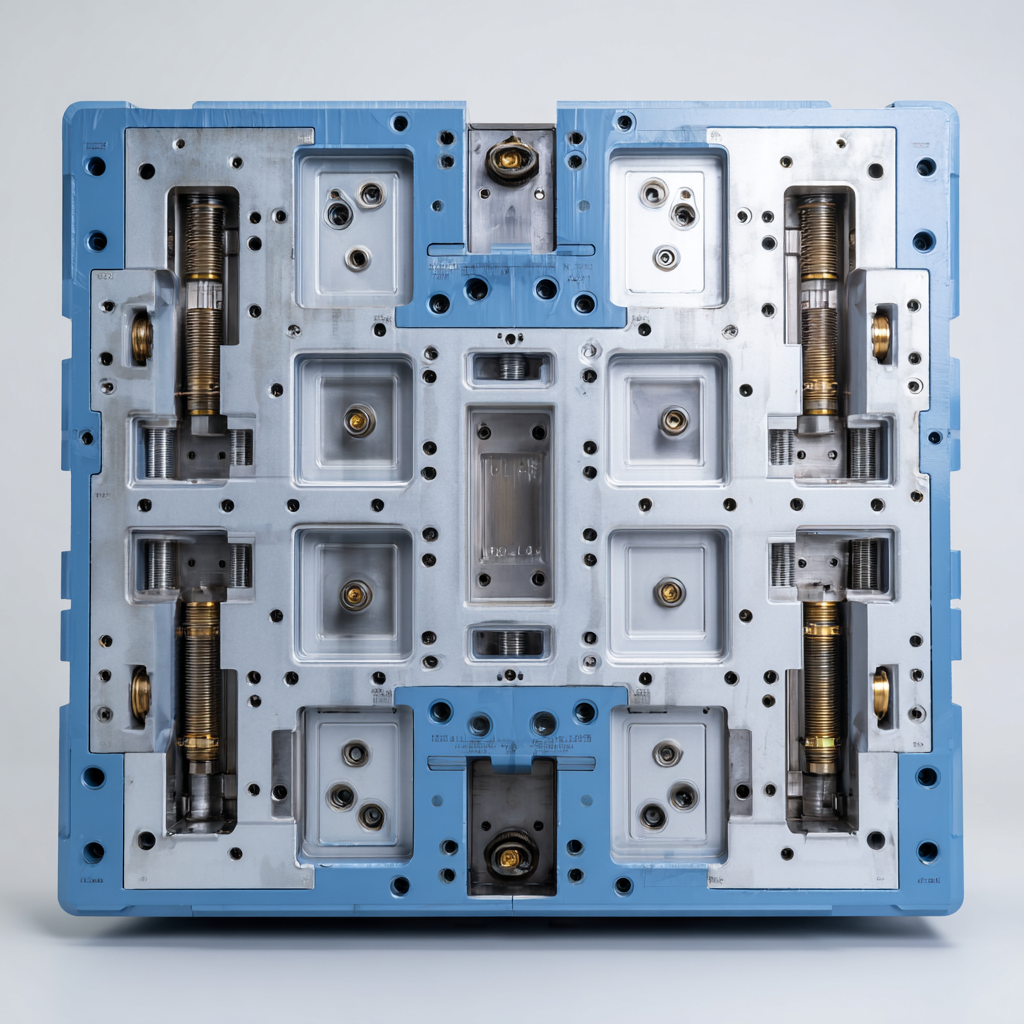

Texin — Reliable Container Injection Molds for Durable, Precise Containers

Texin is committed to providing customers with quality products and services

Texin delivers precision container injection molds for food, cosmetic, medical and industrial containers. From DFM and mold design to material sourcing (45#, 718H, S136, NAK80), CNC/EDM machining, assembly and trial runs, we ensure uniform walls, reliable lid fits, consistent finishes, realistic lead times and warranty support.

Classification:

Precision mold parts

Key words:

Get Quote

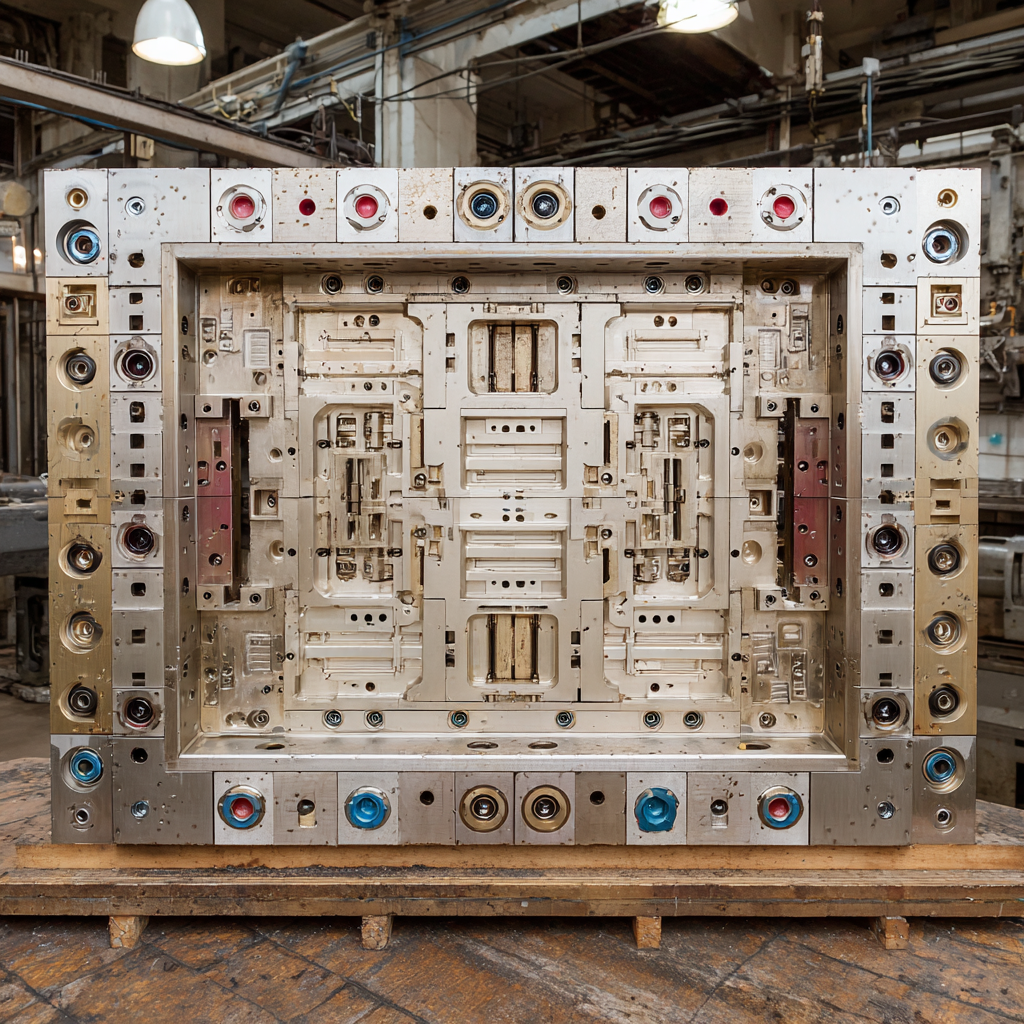

Texin designs and manufactures high-quality container injection molds for a wide range of plastic containers — food jars, storage tubs, cosmetic jars, medical vials, canisters and industrial drums. Containers require more than shape: they demand uniform wall thickness, tight dimensional control for lids/fits, consistent surface finish, chemical resistance and long tool life for high-volume runs. Our container injection molds combine careful DFM, correct steel selection and precision machining so your parts come out right every cycle.

Why container injection molds are special

- Wall uniformity and warpage control: Containers often have thin walls and tall sections; design-for-injection prevents sink and warp.

- Fit and sealing: Lids, threads and snap-fits need repeatable tolerances to ensure sealing and assembly.

- Surface and appearance: Food or cosmetic containers may need smooth or textured finishes; decorative surfaces require mirror-grade steel and polishing.

- Production life: Many containers are high-volume — molds must run thousands to millions of cycles while keeping dimensions and finish stable.

What Texin provides

- End-to-end service: feasibility review → mold design → materials procurement → precision CNC/EDM machining → assembly & debug → trial molding & optimization.

- Fast feasibility and design: initial feasibility checks take 1–3 days; standard mold design 3–7 days (complex designs longer).

- Correct material choices: 45# for low-volume, 718H for mid-volume, S136 (mirror grade) for high-polish/chemical resistance, NAK80 when minimal heat treatment is preferred. Domestic steel is usually available in 1–3 days; imported mirror steels may take 1–4 weeks.

- Realistic cost & schedule view: material typically accounts for ~20–30% of mold cost; machining and processing drive ~30–50% of cost and 40–60% of lead time. Expect machining/parts work to be the largest time component.

- Precision machining: CNC provides micron-level accuracy; EDM/WEDM and polishing deliver required finishes for container faces, threads and sealing surfaces.

- Trial runs: we include at least one official trial (installation, test shots, initial adjustments). Trial runs typically take 1–3 days; 2–3 iterative trials are common for complex molds.

Buyer & producer questions (concise, data-backed)

Q: What files do you need to start? A: Send a 3D model (STEP/IGES/Parasolid) plus a 2D drawing with key dimensions, target material, surface finish and expected annual volume. That enables a 1–3 day feasibility review.

Q: What deliverables are included in design? A: Typical package: mold assembly drawings, cavity/core layout, runner/gate plan, cooling layout and BOM. Moldflow simulation available as optional service.

Q: Which steels do you recommend for containers? A: 45# for prototypes/low volume; 718H for medium runs; S136 for mirror finishes or corrosive use; NAK80 when avoiding heavy heat treatment. Choose by required finish, cycle life and budget.

Q: How long from drawing to first trial? A: Feasibility 1–3 days; design 3–7 days; machining & assembly commonly 2–4 weeks for medium complexity (machining/processing often 40–60% of lead time); trial/validation 1–3 days per run.

Q: What about surface finish options? A: CNC gives base geometry. Mirror finishes require polishing and fine EDM; textured finishes are laser-engraved or chemically etched. For high-gloss containers, use S136 + polishing.

Q: What inspection & tolerance control do you apply? A: Multi-stage inspection with CMM checks, visual inspection and sample validation during trials. We support customer AQL/inspection plans on request.

Q: What is included in trial runs and cost expectations? A: One official trial is included (installation, test shots, initial adjustments). Each trial usually takes 1–3 days. Single trial costs can range from several thousand depending on machine time and adjustments.

Q: Warranty & after-sales? A: We offer an agreed warranty period (typical commercial practice: one year or an agreed number of shots). Spare parts (ejector pins, sleeves) and maintenance services are available.

Quick summary

Container injection molds need careful DFM, correct steel selection (45#, 718H, S136, NAK80), and precision CNC/EDM finishing to ensure uniform walls, sealing fits and consistent finishes over long runs. Texin’s six-stage workflow (feasibility → design → material → machining → assembly → trial) delivers predictable schedules and quality. Material usually represents 20–30% of mold cost; machining and processing are the biggest time and cost drivers (40–60% lead time, 30–50% cost).

If you’re sourcing container injection molds, send Texin your 3D files, 2D key dims, target material and expected volume. We’ll return a feasibility review, timeline and tailored plan to get your container parts into reliable production.

Contact Texin to start your container injection molds project today.

● Many years of mold design, development and manufacturing experience

● Pursue excellence and cast high quality

● High quality, high efficiency and high precision

● Take the initiative to provide timely, fast and dynamic customer service

A simple 3-step process for quickly obtaining a commercial offer

Step 1: Leave your details and our technical specialists will contact you within 24 hours.

Step 2: Confirm the materials for the production process and technical specifications.

Step 3: Get the commercial offer and the lead time.

Previous Page