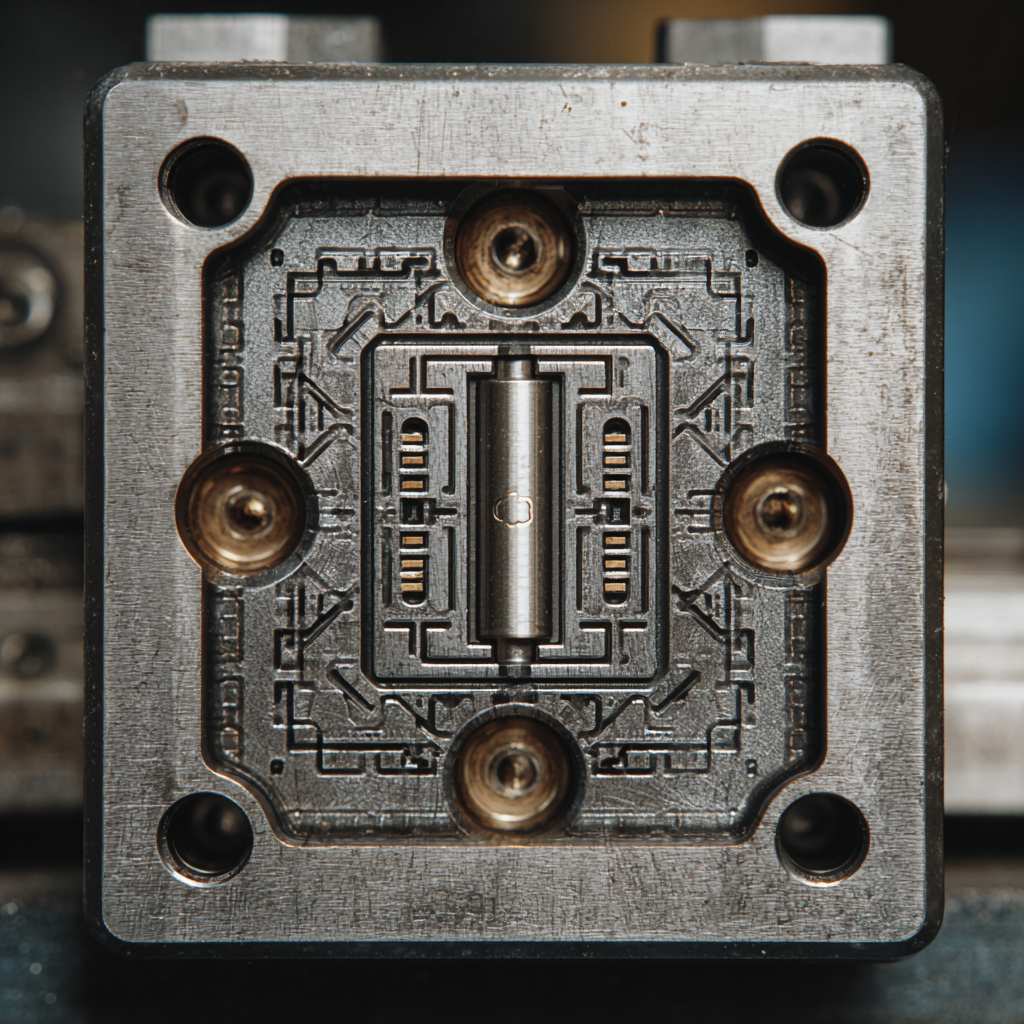

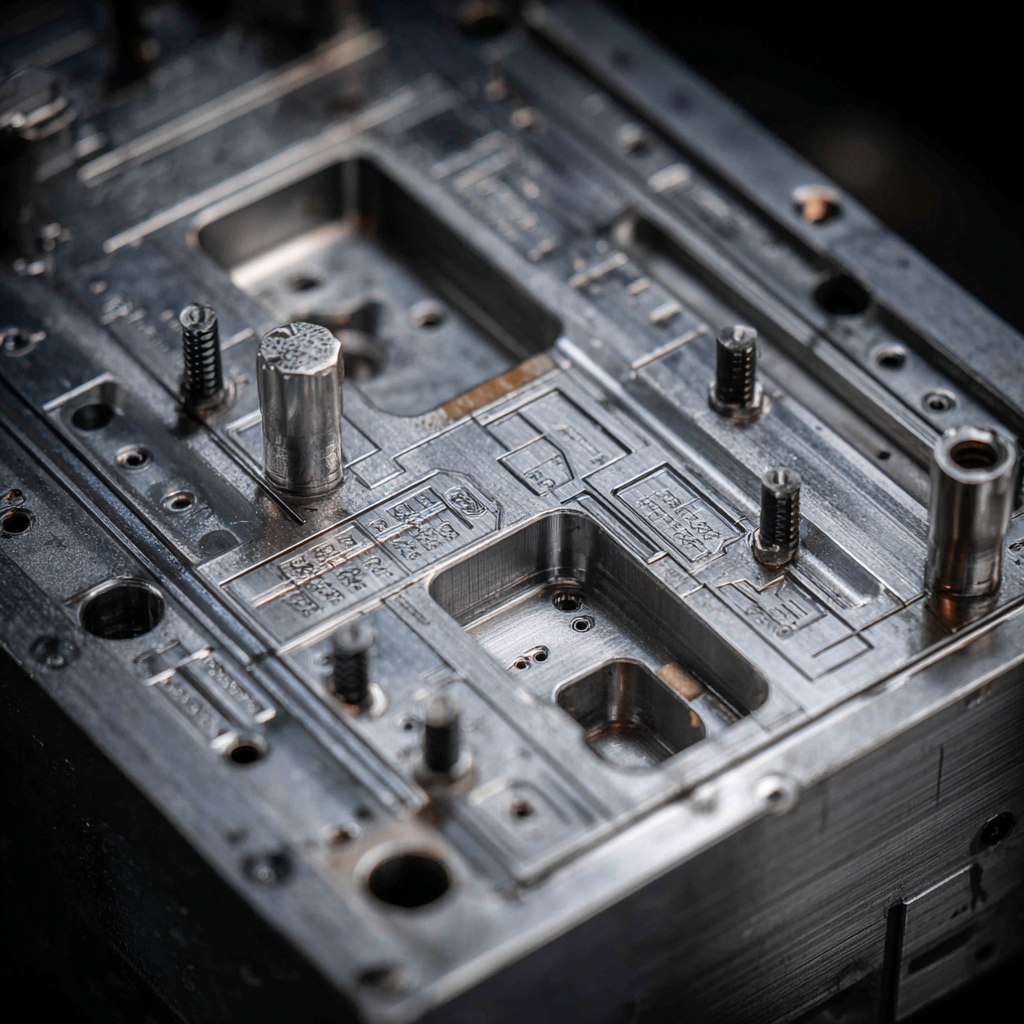

Texin — Robust Injection Molds for Automotive Parts

Texin is committed to providing customers with quality products and services

Texin provides high-precision injection molds for automotive parts, covering feasibility, mold design, material selection (45#, 718H, S136, NAK80), CNC/EDM machining, assembly and trial runs. We deliver durable tools, tight tolerances, consistent finishes, realistic lead times, multi-stage inspection and warranty.

Classification:

Precision mold parts

Key words:

Get Quote

At Texin we design and manufacture durable, high-precision injection molds for automotive parts that must meet strict safety, dimensional and durability requirements. Automotive components — from interior trim, connectors and housings to under-the-hood brackets and clips — demand tight tolerances, long tool life and reliable cycle performance. Our injection molds are engineered to deliver consistent part quality, minimize downtime and support high-volume production.

Why automotive injection molds are demanding

- Long service life: Automotive programs require molds that keep tooling geometry and surface quality stable over long runs — from tens of thousands to millions of shots.

- Tight tolerances & fit: Parts like connectors, snap-fits, and mounting interfaces require repeatable precision so assemblies fit and safety systems function reliably.

- Material & environment: Some automotive parts face heat, chemicals or wear; that affects mold steel selection and surface treatments.

- Aesthetics + function: Interior trims need consistent texture or gloss while functional parts require strict dimensional control — the mold must handle both.

What Texin offers (end-to-end injection molds service)

- Full 6-stage workflow: part feasibility → mold design → material procurement → precision machining → assembly & debug → trial & optimization. These stages reduce late surprises and speed ramp-up to production.

- Fast feasibility checks: initial design-for-injection review in 1–3 days to find wall-thickness, draft or undercut risks.

- Practical design turnaround: standard mold design typically 3–7 days; complex automotive molds may take longer.

- Correct material choices: common tool steels we use include 45# for low-volume, 718H for mid-volume, S136 or similar mirror-grade steels for high-polish/corrosive needs, and NAK80 when as-machined precision without heavy heat treatment is preferred.

- Reliable sourcing: domestic steel is usually available in 1–3 days; imported mirror-grade steels may take 1–4 weeks. Material typically represents ~20–30% of total mold cost.

- Precision machining and finishing: CNC achieves micron-level accuracy for tooling; EDM/WEDM and polishing deliver required surface finishes. Machining/processing normally account for 40–60% of lead time and ~30–50% of mold cost.

- Trial runs & validation: trial molding is scheduled to validate tooling and process (1–3 days per trial). 2–3 iterative trials are common for complex molds.

Key buyer & producer questions — concise answers (data-backed)

Q: What files do you need to start? A: Send a 3D model (STEP/IGES/Parasolid) plus a 2D drawing with key dims, target material and expected annual volume. That lets us perform a 1–3 day feasibility review and provide an accurate quote.

Q: Which steels do you recommend for automotive molds? A: Choose by run length and finish: 45# for low-volume, 718H (pre-hardened) for medium runs, S136 (mirror-grade) for decorative or corrosive environments, and NAK80 for fine cavities that avoid heavy heat treatment. Material choice balances cost, finish and lifespan.

Q: How long from drawing to first trial? A: Typical schedule:

- Feasibility 1–3 days

- Mold design 3–7 days

- Machining & assembly: often 40–60% of total lead time (for medium complexity expect 2–4 weeks)

- Trial/validation: 1–3 days per trial Total: standard molds in weeks; complex automotive molds may take months depending on cavities and finishes.

Q: What about cost breakdown? A: Material is roughly 20–30% of mold cost; machining and processing are the largest shares at ~30–50%. Final quotes vary with cavity count, steel spec and surface finish.

Q: Can you deliver textured or mirror finishes? A: Yes. Base geometry comes from CNC; mirror finishes are achieved with polishing and fine EDM; textures are laser-engraved or chemically treated per sample.

Q: How many trial runs are typical and what do they include? A: We include at least one official trial (installation, test shots, initial adjustments). A single trial typically takes 1–3 days; costs vary (single-trial costs can range from several thousand depending on machine time and adjustments). Additional trials are scheduled if needed.

Q: What inspection and tolerance control do you apply? A: Multi-stage inspection is standard. CNC and finishing deliver micron-level precision for tooling; we perform CMM checks, visual inspections and sample validations during trials. For serial production we support standard AQL/inspection plans on request.

Why choose Texin for automotive injection molds

- Industry-proven process: our six-stage workflow keeps projects predictable.

- Material & schedule transparency: we state typical lead-times (domestic steel 1–3 days; imported 1–4 weeks) and cost proportions (material ~20–30%, machining ~30–50%).

- Skilled finishing: CNC + EDM + polishing for tight tolerances and consistent surface finish.

- Trial-first mindset: trial molding and iterative optimization reduce start-up risk and help reach production quality quickly.

Summary:

Automotive injection molds demand engineering discipline across design, material selection and high-precision machining. Texin brings practical experience and a stage-based process to deliver molds that perform over long production runs while meeting tight tolerances and finish requirements. If you’re sourcing injection molds for automotive parts, send your 3D files, 2D key dims, material spec and expected volume — Texin will return a feasibility review, timeline and tailored plan to get your program into reliable production.

Contact Texin to start your automotive injection molds project — we’ll review your files and respond with a clear plan and timeline.

● Many years of mold design, development and manufacturing experience

● Pursue excellence and cast high quality

● High quality, high efficiency and high precision

● Take the initiative to provide timely, fast and dynamic customer service

A simple 3-step process for quickly obtaining a commercial offer

Step 1: Leave your details and our technical specialists will contact you within 24 hours.

Step 2: Confirm the materials for the production process and technical specifications.

Step 3: Get the commercial offer and the lead time.