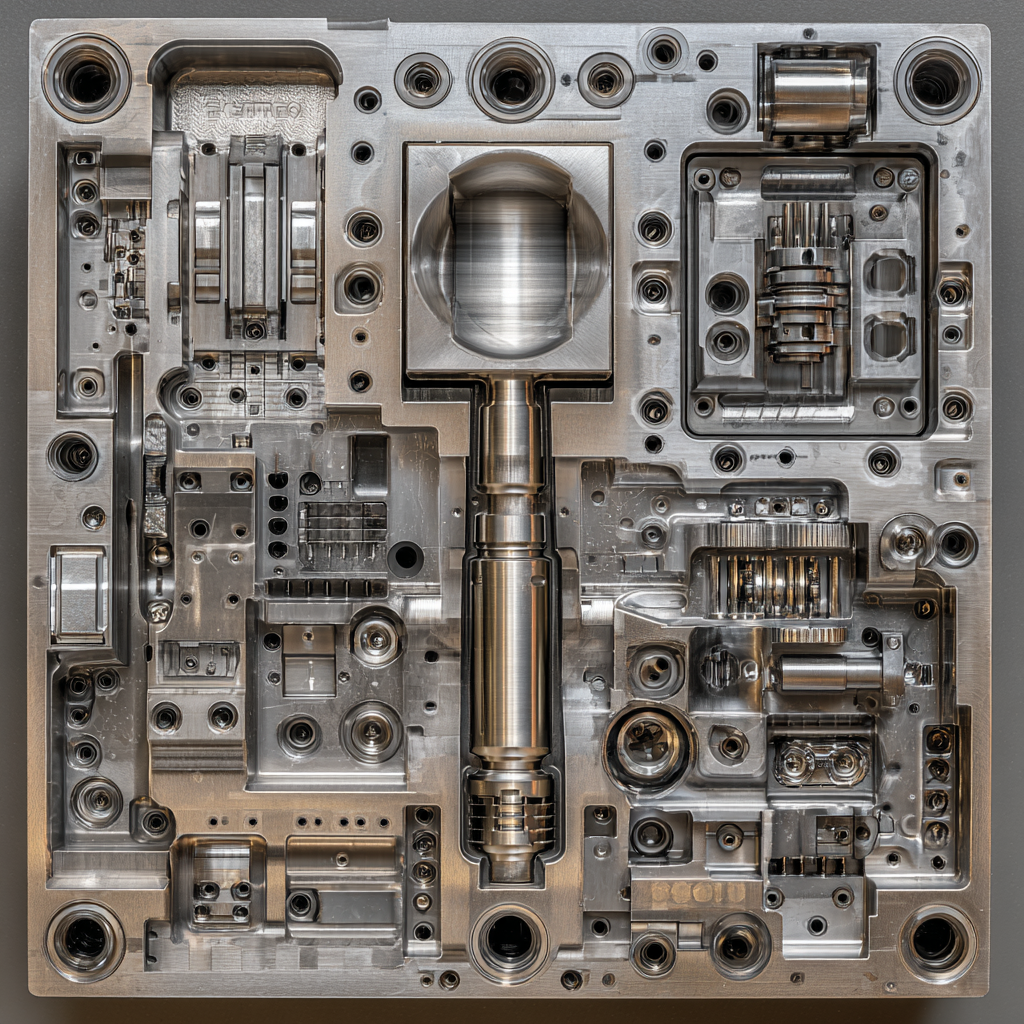

Texin — Precision Electrical Appliances Injection Molds Built to Last

Texin is committed to providing customers with quality products and services

Texin designs and builds high-precision electrical appliances injection molds, covering feasibility, mold design, material sourcing, CNC/EDM machining, assembly and trial optimization. We deliver durable steels (45#, 718H, S136, NAK80), consistent surface finishes, realistic lead times, thorough inspection and warranty support.

Classification:

Precision mold parts

Key words:

Get Quote

At Texin we design and manufacture high-precision electrical appliances injection molds for products that must meet strict functional, cosmetic and safety requirements. Household appliances (small kitchen appliances, vacuum parts, control panels, housings, connectors and switches) demand tight dimensional control, stable surface quality, long tool life and reliable moulding cycles. That’s why manufacturers choose specialized electrical appliances injection molds — and why Texin focuses on the full process, from part feasibility to trial-run optimization.

Why electrical appliances injection molds are different

- Structural demands: Appliance parts often have thin walls, integrated ribs, snap-fits and moving interfaces that require design-for-injection expertise to avoid sink, warp or stress concentration.

- Surface & aesthetics: Many components require consistent textures or mirror-like finishes for consumer appeal — that needs careful mold steel selection and post-processing.

- Durability & cycle life: Appliance production volumes can be high; molds must withstand thousands to millions of cycles while keeping geometry and surface quality stable.

- Functional precision: Switches, button faces and connector housings must meet repeatable tolerances so assembly and safety are reliable.

What Texin delivers

- Full-stage capability: feasibility review → mold design → materials procurement → precision machining → assembly & debug → trial & optimization. (These six core stages are the backbone of our workflow.)

- Professional design review: initial feasibility checks typically take 1–3 days to identify wall-thickness, undercut or draft issues and to propose optimized solutions before tooling begins.

- Rapid & robust mold design: typical mold design turnaround is 3–7 days for standard complexity; complex molds may take longer.

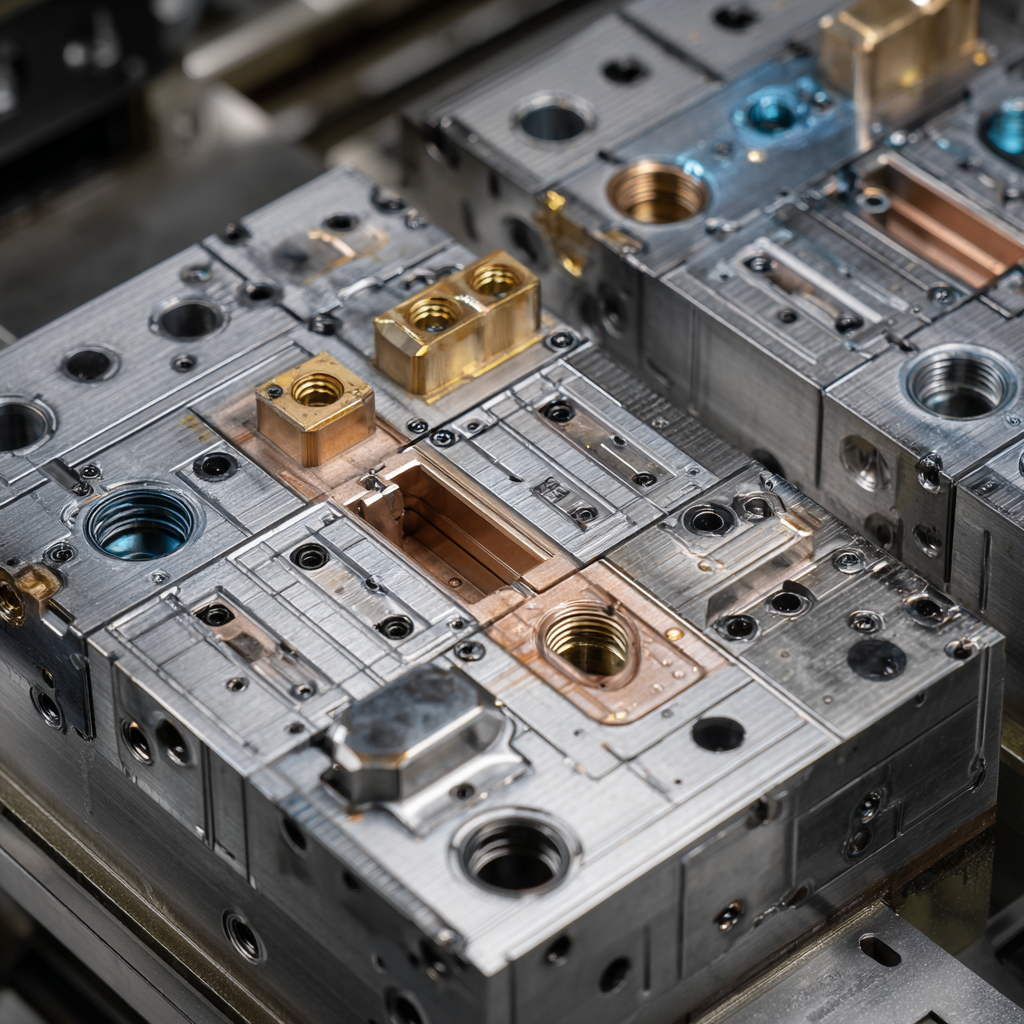

- Correct material choices: we work with common tool steels used in appliance molds — examples include 45# for low-volume, pre-hardened steels like 718H for mid-volume, mirror-grade steels such as S136 for high-polish or corrosive environments, and NAK80 for fine cavities requiring minimal heat treatment.

- Reliable material sourcing: domestic steel is usually available in 1–3 days; imported mirror-grade steels can take 1–4 weeks. Material cost is a major factor and typically represents roughly 20–30% of total mold cost.

- Skilled machining & finishing: CNC is the primary method for mold components (ensuring micron-level accuracy and consistent geometry), followed by EDM/WEDM and polishing for high-finish cavities. CNC provides the precision and consistency critical for electrical appliances injection molds.

- Realistic schedules and cost awareness: machining and parts processing are the most time- and cost-intensive activities — they often account for 40–60% of lead time and 30–50% of total mold cost.

- Trial & optimization: trial runs (trial molding) validate the mold on press, typically done in 1–3 days per trial. If needed, 2–3 iterative trials are common. Single trial costs can range from several thousand to higher depending on machine time and adjustments.

Frequently asked questions (by buyers and producers) — concise answers with data points

Q — What do you need from me to start? A — Best start with a 3D model (STEP/IGES/Parasolid) plus a 2D drawing of key dimensions, target material, surface finish and expected annual volume. That lets us do the 1–3 day feasibility review and quote accurately.

Q — What deliverables will Texin provide during design? A — Typical design package includes: mold assembly drawings, cavity/core layout, runner/gate plan, cooling layout and a parts list/BOM. Moldflow (if required) and additional analysis are available as an extra service.

Q — How long from drawing to first trial? A — Typical schedules:

- Feasibility: 1–3 days

- Mold design: 3–7 days (complex molds longer)

- Machining & assembly: can represent 40–60% of total lead time (for a medium complexity mold expect 2–4 weeks for full machining; very complex molds longer)

- Trial/validation: 1–3 days per trial Total: standard molds often complete in a few weeks; complex appliance molds may be measured in months depending on cavities and special requirements.

Q — Which mold steels do you recommend for electrical appliances? A — For low-volume consumer parts: 45# / mild mold steels. For production with moderate cycle life: pre-hardened steels like 718H. For high polish or corrosive environments (decorative panels or polished bezels): S136 or similar mirror-grade steels. NAK80 is an option when as-machined precision is required without heavy heat treatment. Material choice balances cost, required finish, and expected lifespan.

Q — How much of the mold cost is material vs machining? A — Material typically accounts for about 20–30% of the mold cost; machining and processing are the largest share — around 30–50%. Accurate quoting depends on cavity count, steel spec and surface finish.

Q — What is included in trial mold runs? A — We include at least one official trial (installation, test shots, and initial adjustments). A single trial usually takes 1–3 days; if further optimization is needed, additional trials are scheduled. Trial cost can range from a few thousand depending on machine time and number of adjustments.

Q — What quality, tolerance and inspection can I expect? A — Texin enforces inspection at multiple stages. Typical dimensional precision for mold components is at the micron scale (CNC plus finishing), and we perform CMM checks, visual inspections and sample validation during trials. For serial part inspection, common industry AQL/inspection plans are supported on request.

Q — Surface finish — can you deliver mirror or textured finishes? A — Yes. Rough machining and CNC provide the base geometry; mirror finishes are achieved through polishing and fine EDM finishing. For textured surfaces, we can engrave textures or apply chemical etch/texturing methods per sample.

Q — What about warranty and post-delivery support? A — We support trial validation and an agreed warranty period. Typical commercial practice (and our standard offers) include a warranty timeframe (for example one year or an agreed number of shots) and defined terms for repairs of manufacturing defects. Spare parts (e.g., ejector pins, sleeves) and maintenance services can be supplied as a follow-up service.

Quick summary

— why Texin for electrical appliances injection molds Electrical appliances injection molds require engineering discipline across design, material selection, high-precision machining and structured trial optimization. Texin combines a stage-based workflow (feasibility → design → material → machining → assembly → trial) with experienced CNC/EDM finishing and practical scheduling. We balance cost and quality — material typically 20–30% of cost while machining and processing drive the bulk of time and price (40–60% of lead time, 30–50% of cost). Texin’s approach minimizes late-stage surprises and gets your product into production with predictable quality and predictable cadence.

If you are sourcing injection molds for electrical appliances and need reliable, production-ready results, contact Texin for a feasibility review — send your 3D files, 2D key dims, material and expected volume and we’ll respond with a tailored plan and timeline.

● Many years of mold design, development and manufacturing experience

● Pursue excellence and cast high quality

● High quality, high efficiency and high precision

● Take the initiative to provide timely, fast and dynamic customer service

A simple 3-step process for quickly obtaining a commercial offer

Step 1: Leave your details and our technical specialists will contact you within 24 hours.

Step 2: Confirm the materials for the production process and technical specifications.

Step 3: Get the commercial offer and the lead time.