Texin: Building Confidence into Every Medical Injection Mold

Texin is committed to providing customers with quality products and services

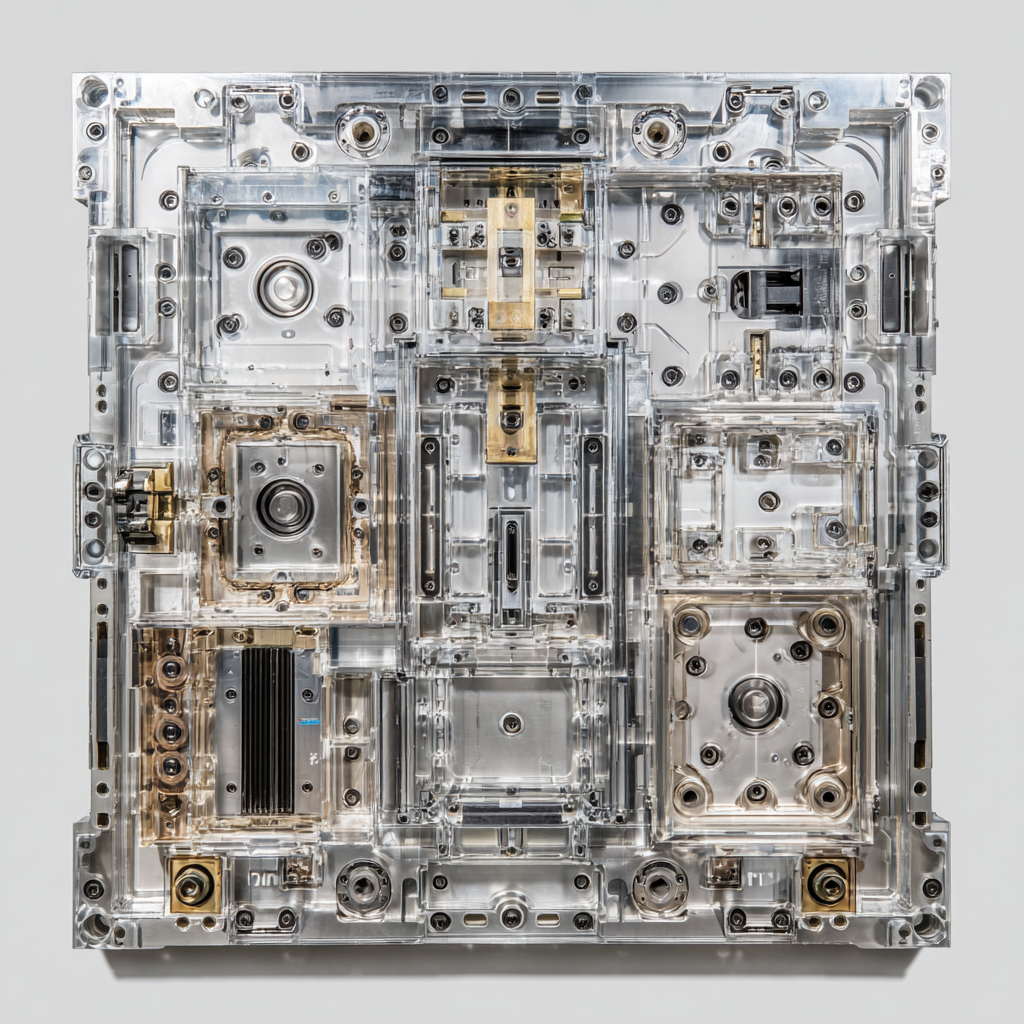

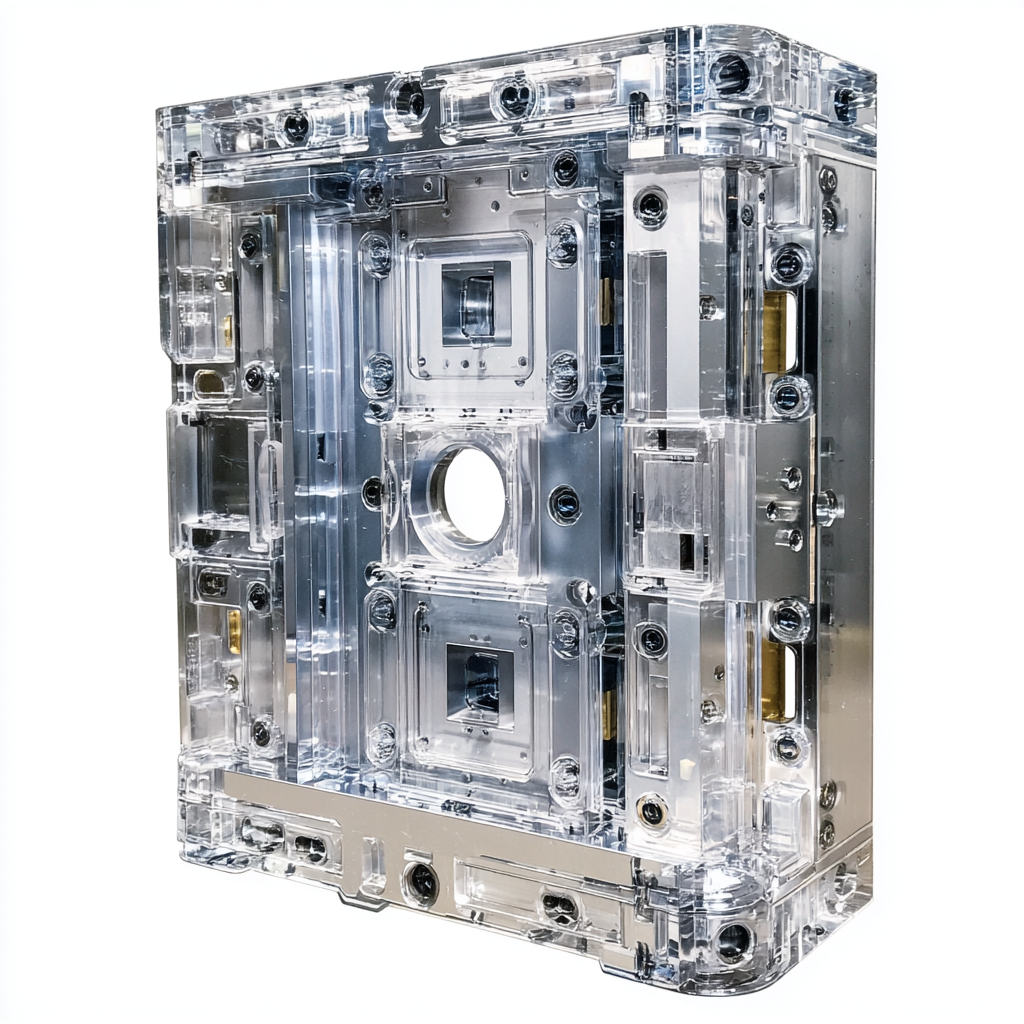

Texin engineers high-precision medical injection molds for life-saving devices. We meet the strictest standards, ensuring flawless, reliable components for your critical projects. Partner with us for confidence and quality in every mold.

Classification:

Precision mold parts

Key words:

Get Quote

Texin: Building Confidence into Every Medical Injection Mold

We get it. When you're developing a medical device, the pressure is immense. Your name is on that project. You're balancing tight budgets, aggressive timelines, and the absolute, non-negotiable demand for perfection. The plastic components you need might seem like a small part of the puzzle, but you know that a flawless part comes from a flawless mold. A single-micron error in a tool can lead to a failed validation, a delayed launch, and a massive headache you just don't need.

That's where we come in. At Texin, we don't just build medical injection molds; we build the confidence and peace of mind you need to succeed. We’ve built our reputation in the high-stakes industries of medical, automotive, and electronics, and we understand that what you’re really looking for isn’t just a supplier, but a partner who takes your success as seriously as you do.

Your Core Concerns, Our Concrete Answers

When you're sourcing medical injection molds, the questions you have are specific and technical. You're not just buying a product; you're vetting a process and a team. Here are the tough questions we think you should be asking, and our straightforward answers.

1. "My part design is complex. How do I know it can even be molded correctly before I commit to the cost?"

This is the most critical question, and it's why our process always begins with a deep-dive Design for Manufacturability (DFM) analysis. We'll take your 3D models and, within 1 to 3 days, provide you with a detailed report. We don't just run it through a piece of software; our engineers will personally flag potential issues like tricky undercuts, uneven wall sections that could cause sink marks, or sharp corners that create stress points. This isn't just a formality—it’s a collaborative step to prevent costly mold modifications down the road.

2. "Mold steel is a huge cost factor. How do you justify using an expensive grade like S136?"

You're right, the material cost can be 20%-30% of the total mold price, and it's a place where others might cut corners. We don't. Our recommendation is always tied directly to your project's reality.

- Running a million+ disposable parts annually? You need hardened steel like S136 or H13. They resist the wear and tear of high-volume production and ensure your 1,000,000th part is identical to your first.

- Need optical clarity or chemical resistance? We’ll specify a high-polish, corrosion-resistant steel like imported S136. There’s no substitute.

- Lower volume, but high precision? A pre-hardened steel like NAK80 might be the perfect balance of performance and cost. We lay out the pros and cons so you can make an informed decision, not just a cheap one.

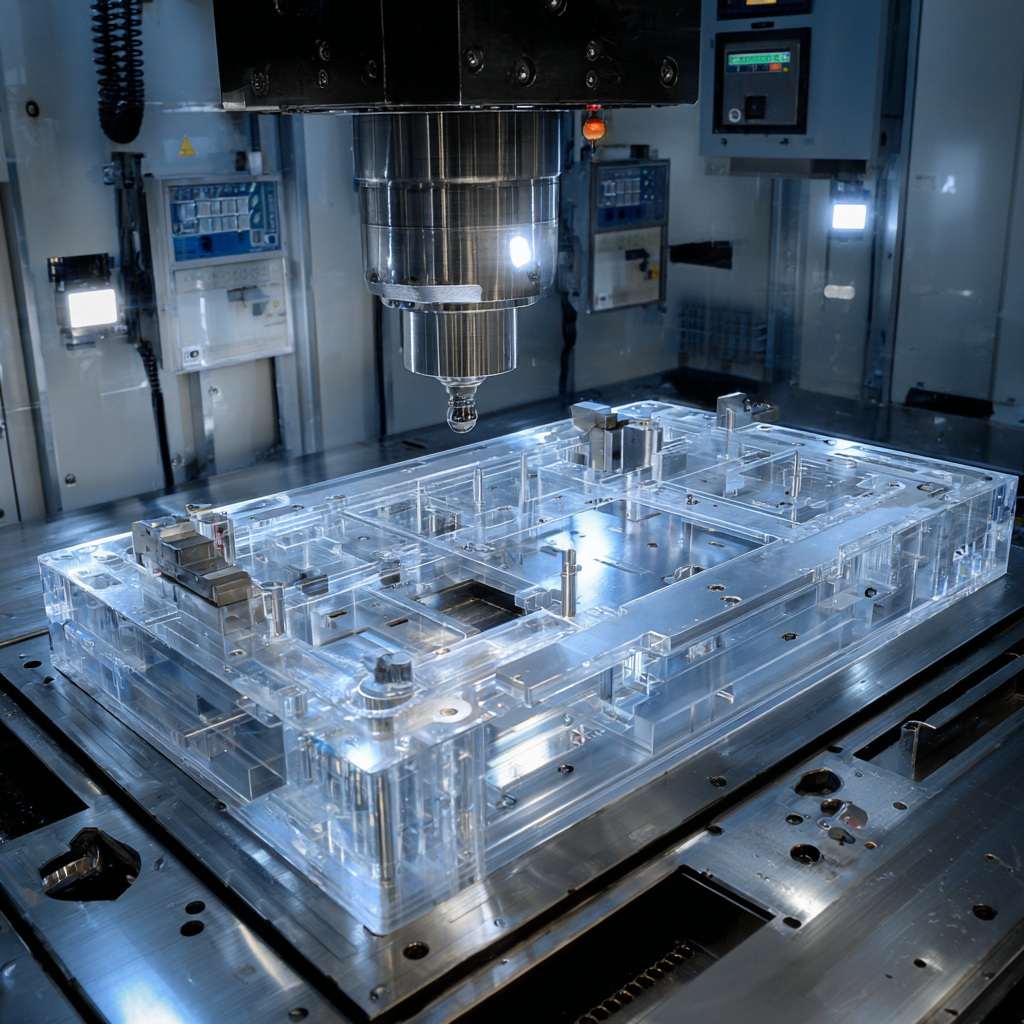

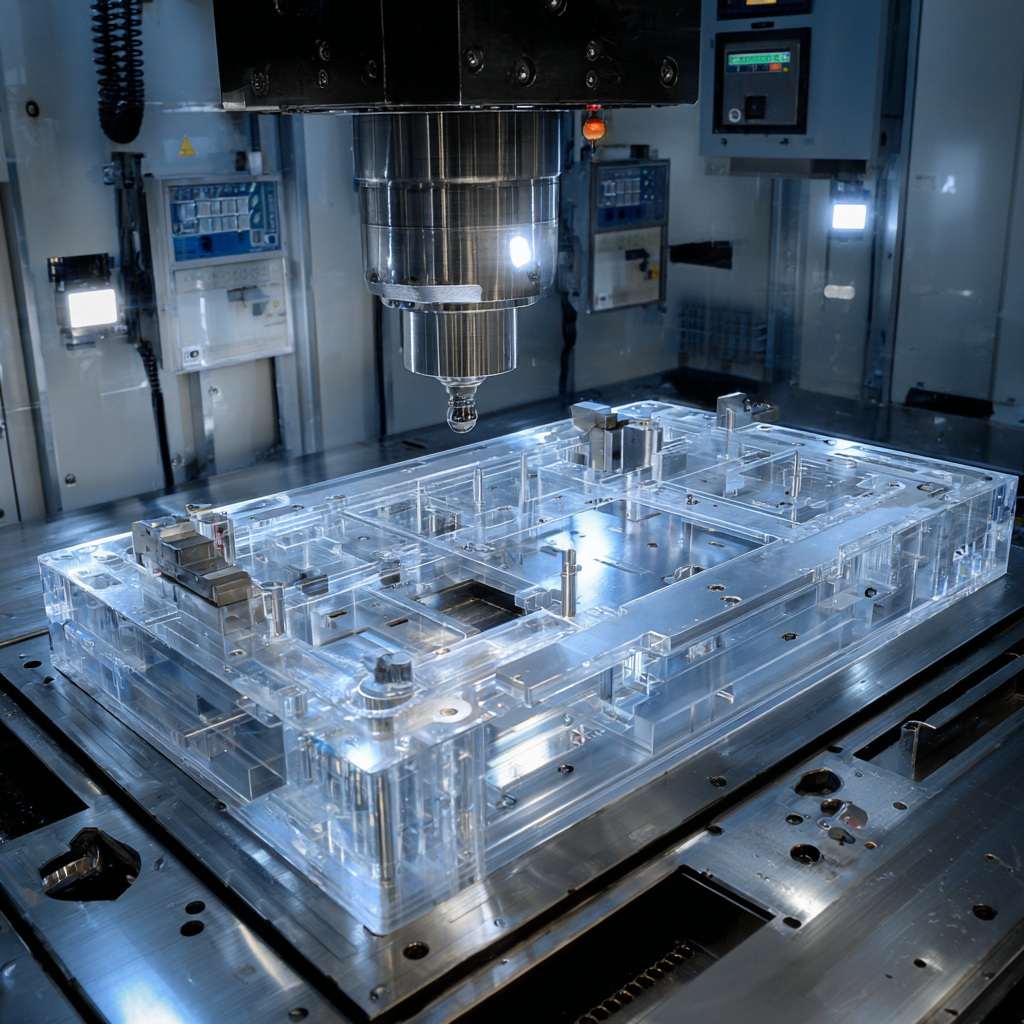

3. "The mold machining phase is a black box. How can I be sure my project isn't just sitting on a workshop floor?"

We believe in total transparency. The machining stage is the longest part of the journey, often taking up 40% to 60% of the entire mold-build timeline (typically 2-4 weeks for a standard mold). To take the mystery out of it, we provide weekly progress reports with photos. You will see your mold taking shape, from the initial CNC roughing to the intricate details being formed by EDM and the final polishing touches. You’ll never have to wonder where your investment stands.

4. "What happens when you test the mold? What exactly do I get back?"

The first trial, or T1, is the moment of truth. When we send you those first samples, they don't come alone in a box. You will receive a complete qualification package, including:

- The T1 Samples: The physical parts for your review and testing.

- A Full Dimensional Report (FAI): We measure the critical features of the samples with our CMM and document how they stack up against your 2D drawings. No guessing.

- The Molding Process Sheet: A "recipe card" that shows the exact temperatures, pressures, and cycle times we used. This proves the process is stable and repeatable for mass production.

If there are any deviations due to our workmanship, the subsequent mold adjustments and trial runs are on our dime. Period.

More Than a Mold, It's a Partnership

Ultimately, choosing a manufacturer for your medical injection molds comes down to trust. It's trusting that the team you hire has the technical mastery, the right equipment, and—most importantly—the integrity to see your project through to success.

At Texin, we're not just machinists and engineers; we are problem-solvers who take immense pride in playing a small but vital role in the advancement of medical technology. Your project is not just another job number for us. It's a responsibility we take personally. Let’s build something great together.

Ready to start the conversation? Reach out to the Texin team to discuss your project.

● Many years of mold design, development and manufacturing experience

● Pursue excellence and cast high quality

● High quality, high efficiency and high precision

● Take the initiative to provide timely, fast and dynamic customer service

A simple 3-step process for quickly obtaining a commercial offer

Step 1: Leave your details and our technical specialists will contact you within 24 hours.

Step 2: Confirm the materials for the production process and technical specifications.

Step 3: Get the commercial offer and the lead time.

Next Page