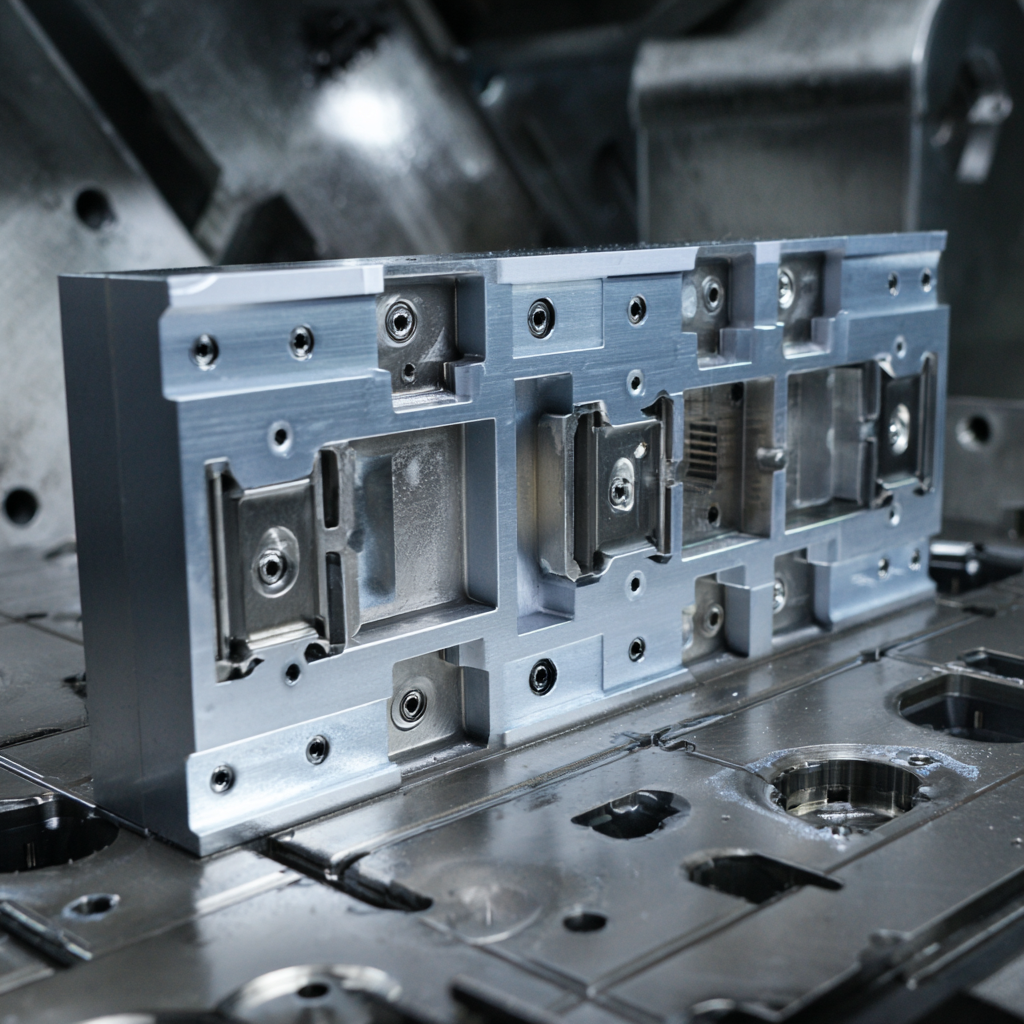

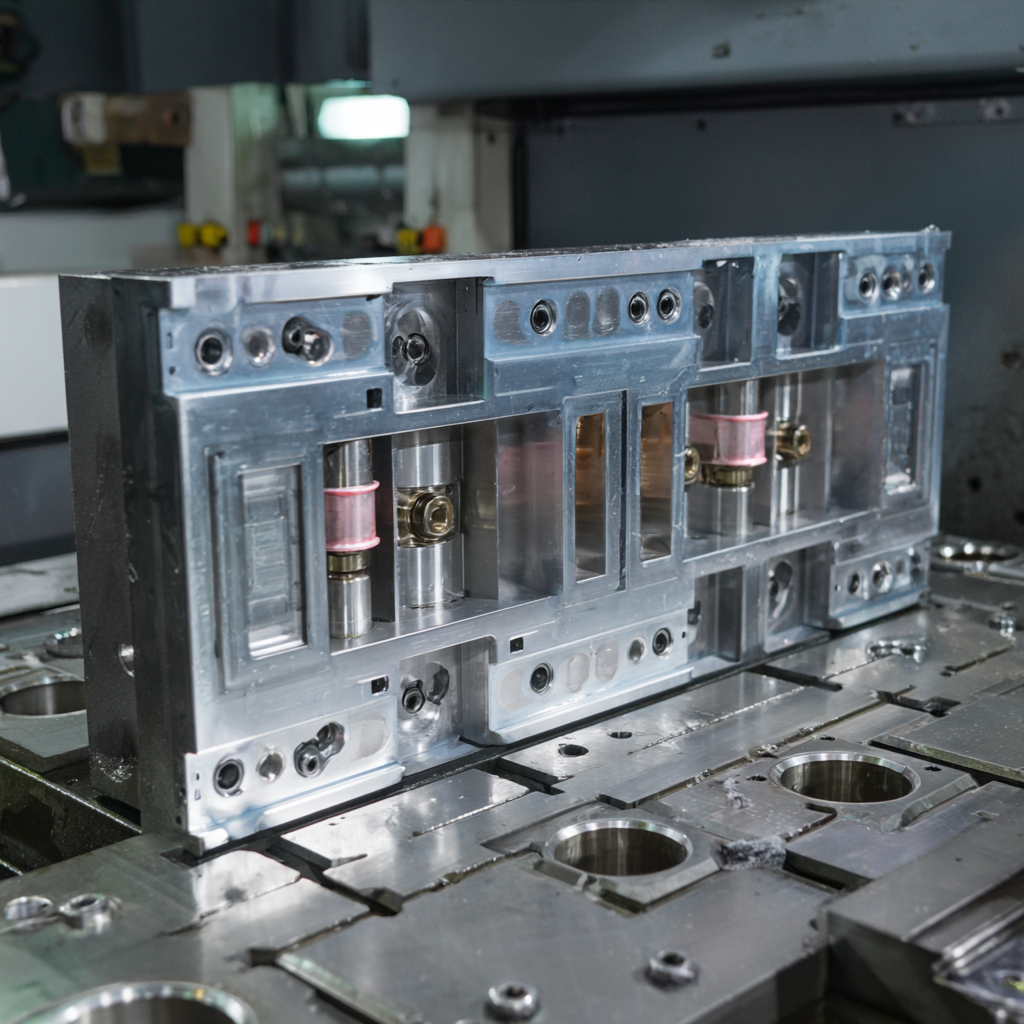

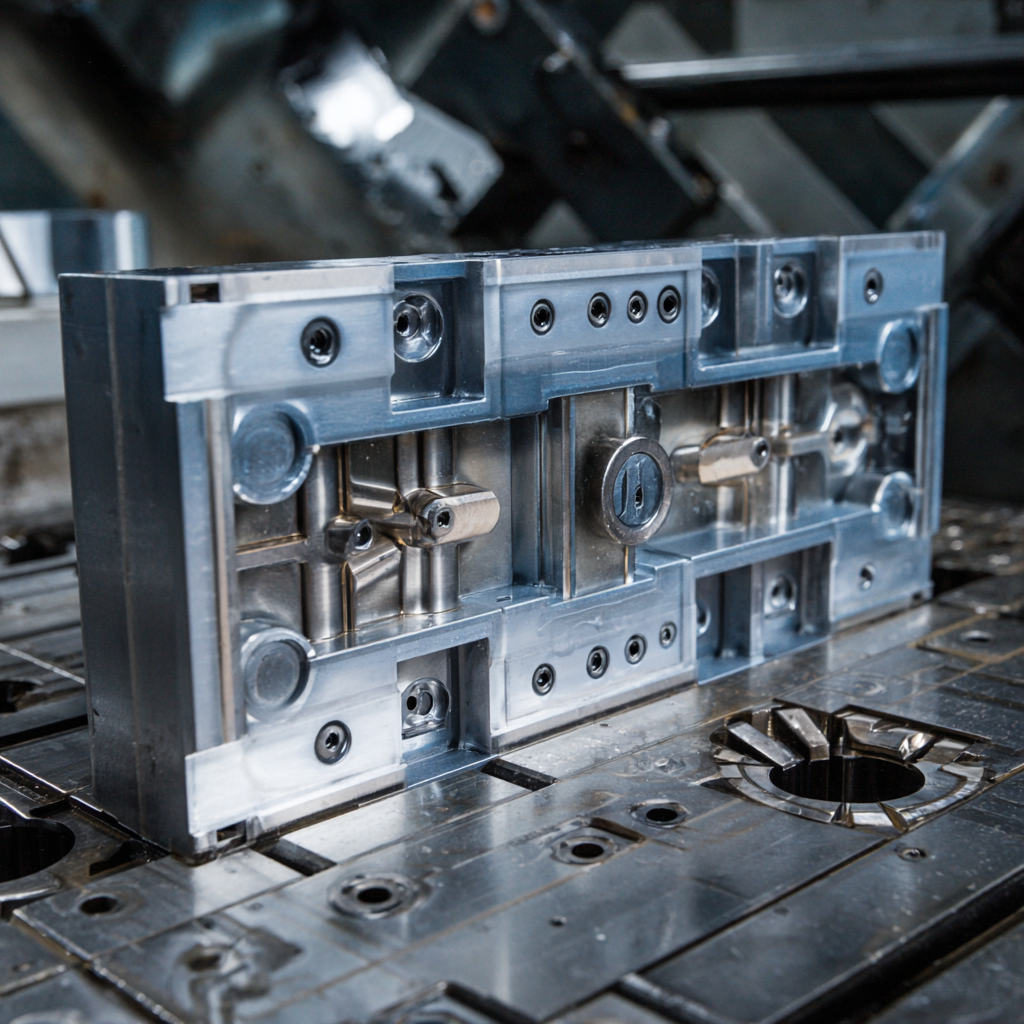

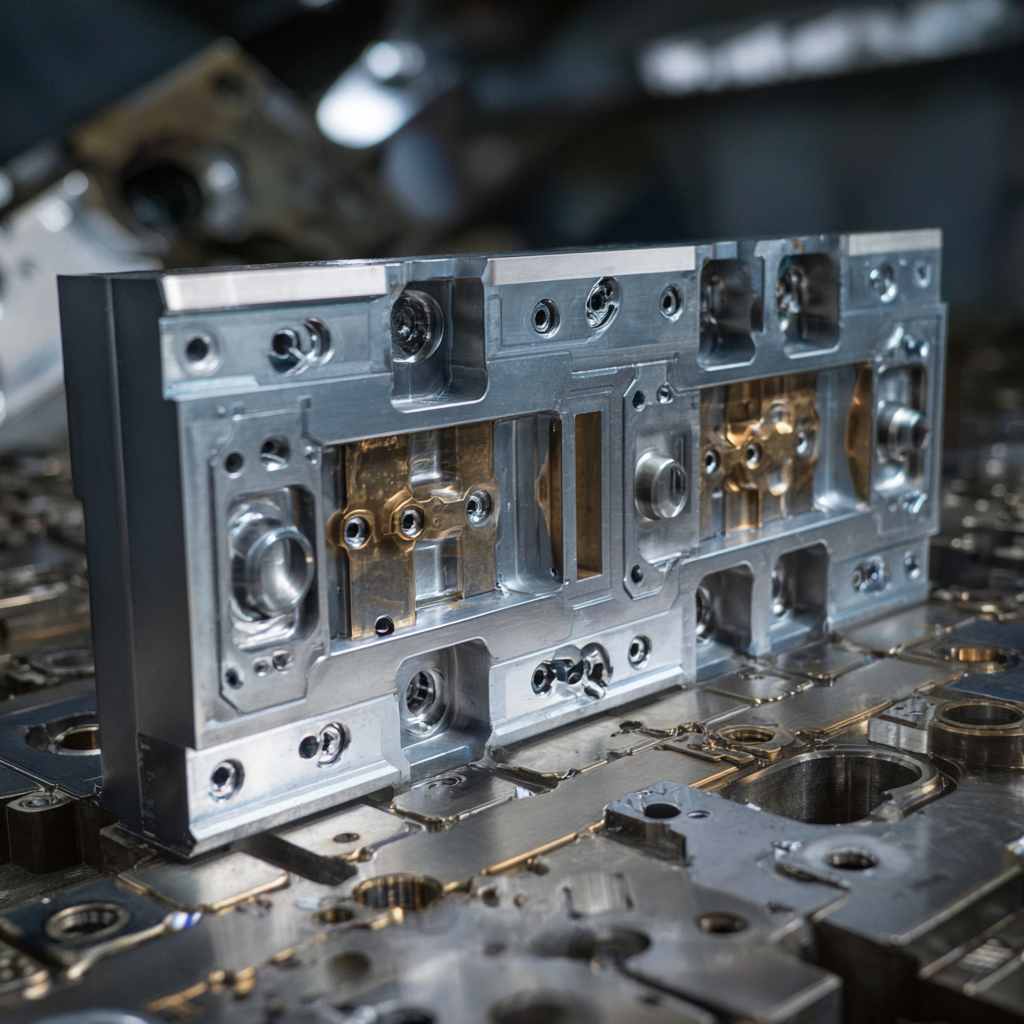

Texin — Precision Snap-Fit Parts Injection Molds

Texin is committed to providing customers with quality products and services

Texin specializes in precision snap-fit injection molds—end-to-end DFM, mold design, materials (45#, 718H, S136, NAK80), CNC/EDM finishing and trial optimization. We deliver micron-level accuracy (critical tolerances ±0.005–0.01mm), mirror/textured finishes, optional Moldflow, CMM inspection, 1–3 day trials and warranty support.

Classification:

Precision mold parts

Key words:

Get Quote

Precision snap-fit parts injection molds demand exacting engineering. Snap-fits are functional features: they must flex reliably, lock and unlock repeatedly, and hold precise alignment while resisting wear and stress. Tolerances are tight, draft angles and wall thickness must be engineered to avoid stress concentration, and surface finish and material choice directly affect assembly performance and lifecycle. At Texin we specialize in Precision snap-fit parts injection molds, delivering tooling and processes that meet the demanding requirements of electronics, appliances, automotive connectors and other high-precision applications.

Why Precision snap-fit parts injection molds are challenging

- Tight functional tolerances: Snap-fit geometry controls engagement force and retention; small dimensional changes (microns) change performance.

- Thin sections and flex zones: Many snap-fits use thin living hinges or cantilever beams that require careful wall-thickness control to avoid sink, warp or premature failure.

- Undercuts and locking features: These often require slides/cores, adding mold complexity and precision assembly requirements.

- Repeatability & life: Molds must produce consistent parts over many cycles; steel grade and finishing affect tool life and surface wear.

- Appearance + function: Many snap-fits are hidden but require smooth surfaces in contact areas; some are visible and require consistent texture or polish.

What Texin delivers

- Full 6-stage service: feasibility → mold design → material procurement → precision machining → assembly & debug → trial & optimization. These stages reduce startup risk and speed production ramp-up.

- Fast feasibility checks: initial DFM and feasibility typically take 1–3 days to flag wall-thickness, draft, undercut or mold-action issues and propose fixes before tooling begins.

- Solid mold design turnaround: standard mold design 3–7 days; complex multi-slide/tooling designs may take longer.

- Correct material choices: for precision snap-fit molds we select steel by expected life and finish: 45# for prototypes/low-volume, 718H pre-hardened for medium runs, S136 (mirror-grade) for high-polish or corrosive conditions, and NAK80 where as-machined precision or minimal heat treatment is needed. Domestic steel is typically available in 1–3 days; imported mirror steels may take 1–4 weeks.

- Precision machining & finishing: CNC provides micron-level geometry and consistency; EDM/WEDM and polishing finish critical contact and flex surfaces. Machining and processing are the major time/cost drivers (40–60% of lead time, 30–50% of mold cost). Material usually represents ~20–30% of mold cost.

- Trial & optimization: trial molding validates fit, flex and retention. Each trial typically takes 1–3 days; 2–3 iterative trials are common for complex snap-fit features.

Buyer & producer FAQs (concise, data-backed)

Q — What do you need to start? A — Send a 3D model (STEP/IGES/Parasolid) plus a 2D drawing with key dimensions, target material, surface finish and expected annual volume. That enables a 1–3 day feasibility review and accurate quote.

Q — How precise can you make snap-fit features? A — Mold components are machined to micron-level repeatability. We perform CMM inspection and sample validation during trials; typical achievable tolerances depend on geometry but are commonly in the ±0.01 mm to ±0.005 mm range for critical features when specified.

Q — Which steels are best for long-life snap-fit molds? A — Choice depends on run length and finish: 718H for medium-volume production, S136 for mirror-polished or corrosive environments, and H13 or similar grades for high wear/heat resistance. Material selection balances cost and expected cycle life.

Q — What about trial runs and corrections? A — We include at least one official trial (installation, test shots, initial adjustments). A single trial usually takes 1–3 days; additional trials are scheduled as needed. Typical trial costs depend on machine time and adjustments; iterative optimization (2–3 trials) is common for complex snap-fit function tuning.

Q — Surface finish and texture? A — Critical contact surfaces often require fine finishes: mirror polishing (after EDM/fine machining) or specific Ra values. Textures or logos are laser-engraved or chemically etched per sample. We deliver polishing and EDM work to meet functional and aesthetic targets.

Q — How does cost break down? A — Material ~20–30% of mold cost; machining/processing ~30–50%; design, assembly and testing make up the remainder. Machining/processing also account for 40–60% of lead time.

Q — What inspection do you provide? A — Multi-stage inspection: in-process checks, CMM reports for critical dimensions, surface roughness (Ra) checks and first article / sample validation during trial runs. AQL/inspection plans for serial production are supported on request.

Practical design tips we apply (so your snap-fit works first time)

- Keep wall thickness uniform around flex zones to reduce sink and stress.

- Provide sufficient draft where possible, but design living hinges and cantilevers with controlled thickness and radii.

- Specify critical dimensions and tolerances for engagement features upfront — this helps us allocate machining precision and inspection steps.

- If undercuts are unavoidable, plan for slides or lifters in the mold design and note required stroke and life.

Summary:

Precision snap-fit parts injection molds require careful DFM, precise mold steel selection (45#, 718H, S136, NAK80), micron-level CNC machining, EDM/fine finishing and structured trial validation. Texin combines a six-stage workflow with experienced tooling, CNC/EDM capability and practical scheduling to deliver Precision snap-fit parts injection molds that perform reliably in assembly, sustain repeated cycles and meet tight functional tolerances. Send us your 3D files, 2D key dims, material spec and expected volume — Texin will return a feasibility review, realistic timeline and tailored plan to get your snap-fit parts into consistent production.

Contact Texin for a feasibility review on your Precision snap-fit parts injection molds project.

● Many years of mold design, development and manufacturing experience

● Pursue excellence and cast high quality

● High quality, high efficiency and high precision

● Take the initiative to provide timely, fast and dynamic customer service

A simple 3-step process for quickly obtaining a commercial offer

Step 1: Leave your details and our technical specialists will contact you within 24 hours.

Step 2: Confirm the materials for the production process and technical specifications.

Step 3: Get the commercial offer and the lead time.