How Injection Molding Improves the Durability of Water Dispenser Shells

Release time:

Sep 16,2025

Tip: Using high-quality materials and strict processes increases the lifespan of water dispenser shells.

Key Takeaways

- Injection molding enhances the durability of water dispenser shells, making them last longer and reducing the need for replacements.

- Choosing high-quality materials like polycarbonate and ABS ensures resistance to impacts, heat, and moisture, keeping the shell safe and attractive.

- Precision in manufacturing leads to tight fits and low warpage, which prevents leaks and assembly issues, ensuring consistent quality.

- Regular mold maintenance and careful cooling control are essential for extending the life of molds and improving the quality of the final product.

- Advanced techniques like in-mold decoration and overmolding not only enhance appearance but also add durability, making shells resistant to scratches and fading.

Durability in Water Dispenser Shells

What It Means

When I talk about durability in water dispenser shells, I focus on how well the shell stands up to daily use. I look for materials that resist impacts, heat, and moisture. A durable shell keeps its shape and color, even after years of handling and cleaning. I want the shell to protect the internal parts from bumps and drops. I also expect it to stay safe for food and water contact.

I use advanced plastics like polycarbonate (PC) and acrylonitrile butadiene styrene (ABS) because they offer strong resistance to cracks and warping. I also choose PBT/PET with glass fiber for extra strength. These materials help the shell survive in kitchens, offices, and public spaces.

Note: I always check that the shell meets safety standards, so it does not break or degrade when exposed to heat or steam.

Why It Matters

I know that a durable water dispenser shell protects both the machine and the people who use it. If the shell cracks or warps, water can leak or bacteria can grow. That puts users at risk. Manufacturers also face problems if shells fail early. They may need to replace parts or deal with unhappy customers.

I want every shell to last as long as possible. This saves money and reduces waste. It also builds trust in the brand. When I use injection molding with the right materials and processes, I make sure the shell stays strong, safe, and attractive for years.

- A strong shell means fewer repairs.

- Good materials keep the shell looking new.

- Reliable shells help companies meet safety rules.

Tip: I always recommend choosing shells made with advanced injection molding for the best results.

Injection Molding Benefits

Material Choices

When I select materials for water dispenser shells, I focus on strength, safety, and appearance. I rely on polycarbonate (PC), acrylonitrile butadiene styrene (ABS), and PBT/PET with glass fiber. These materials offer high impact resistance and thermal stability. I know that the right material choice helps the shell withstand daily bumps and exposure to heat. I always check that each material meets food safety standards. This step is essential for protecting users.

Tip: I recommend using PC for transparent windows and ABS for textured housings. PBT/PET with glass fiber adds extra strength where needed.

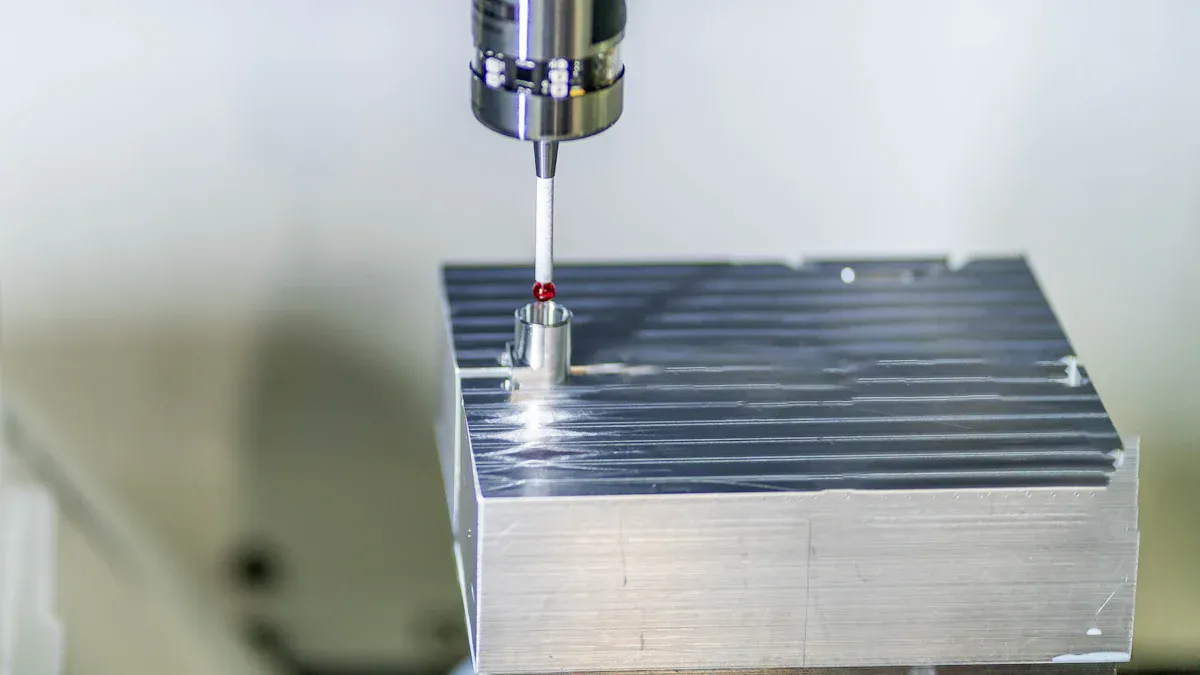

Precision and Consistency

I use precision injection molding to create shells with tight fits and low warpage. This approach ensures that every part matches the design exactly. I know that consistent results make assembly easier and prevent leaks. I rely on advanced machines and strict quality control at every step. I inspect each shell for defects and measure critical dimensions. My team tracks data to catch any issues early.

- I check mold temperature and pressure during each manufacturing process.

- I use automated sensors to monitor quality control.

- I compare samples from each batch to maintain consistency.

Note: Tight tolerances and reliable assembly reduce the risk of poor fit and future repairs.

Advanced Processes

I use advanced techniques like in-mold decoration (IMD) and overmolding to improve both appearance and durability. IMD lets me add graphics and textures directly during the manufacturing process. Overmolding allows me to combine different materials for extra protection. These methods create shells that resist scratches and keep their color over time. I always test new finishes for strength and safety.

Alert: Advanced processes help me deliver shells that look great and last longer.

- IMD adds logos and patterns without extra steps.

- Overmolding protects edges and corners from damage.

- I use strict quality control to check every finish.

Best Practices for Longevity

Mold Maintenance

I always prioritize mold maintenance to extend injection mold life and ensure mold longevity. Regular cleaning and inspection help me spot wear before it affects production cycles. I replace worn components quickly. This approach keeps the mold in top condition and prevents defects in water dispenser shells. I track mold longevity by recording each maintenance session and monitoring the number of production cycles completed. My team uses specialized tools to clean vents and cooling channels. I believe that consistent mold maintenance is the foundation for reliable results.

Tip: I schedule mold checks after every set of production cycles to catch issues early.

Cooling and Cycle Control

I know that cooling and cycle control play a big role in mold longevity and injection mold life. I use shell and tube heat exchangers to keep temperatures steady during production cycles. Precise temperature control helps me avoid warping and other defects. Uniform cooling means each shell comes out with the same quality. I monitor cooling rates and adjust cycle times to match the material and mold design. This process reduces rejects and keeps production cycles efficient.

Note: I always adjust cooling and cycle control to maximize mold longevity and keep injection mold life at its best.

Surface Protection

I select flame-retardant materials rated UL94 to protect water dispenser shells from heat and fire hazards. These materials help me meet electrical safety standards and improve mold longevity. I also provide compliance support with MSDS, RoHS, and REACH documentation. This ensures every shell is safe for users and ready for global markets. I test each batch for durability and heat resistance. My customer service team responds quickly to any questions about safety or compliance.

Alert: Using flame-retardant materials and strong compliance support helps me deliver shells that last through many production cycles.

Solving Durability Issues

Common Problems

I often see several issues that affect the durability of water dispenser shells. The most common problems include:

- Cracking after impact or during use

- Warping that causes poor fit or leaks

- Yellowing from heat or UV exposure

- Poor fit between parts, leading to assembly issues

These problems usually come from molding defects. Cracking can happen if the material does not fill the mold evenly. Warping often results from uneven cooling or poor mold design. Yellowing appears when the plastic cannot resist heat or sunlight. Poor fit comes from inconsistent molding or low-quality materials.

Tip: I always check for molding defects early to prevent bigger problems later.

Injection Molding Solutions

I use injection molding to solve these durability issues. I select materials like PC, ABS, and PBT/PET with glass fiber to reduce molding defects. These materials resist cracking and yellowing. I control temperature and pressure during the process to avoid warping. I design molds with tight tolerances to ensure a good fit. I monitor every step to catch molding defects before they reach the next stage.

- I use sensors to track temperature and pressure.

- I inspect each shell for molding defects.

- I adjust the process if I see signs of warping or poor fit.

Note: Careful control of injection molding helps me reduce molding defects and improve shell durability.

Texin’s Approach

At Texin, I take extra steps to prevent molding defects. I use rapid prototyping to test designs before full production. I apply design for manufacturability (DFM) to spot potential molding defects early. My team supports customers through every stage, from design to delivery. I provide detailed reports on molding defects and suggest improvements. I believe that strong support and advanced technology help me deliver shells with fewer molding defects.

Alert: My focus on quality and support means fewer molding defects and longer-lasting water dispenser shells.

I see injection molding as the foundation for strong, safe, and visually appealing water dispenser shells. My experience with advanced materials and precise processes helps me deliver products that last. I follow strict quality control and compliance standards. Industry experts recommend choosing partners with specialization, experience, and advanced technology. Here is what they suggest:

I encourage you to choose Texin for reliable, high-quality solutions.

FAQ

What materials do I use for water dispenser shells?

I use polycarbonate (PC), ABS, and PBT/PET with glass fiber. These materials offer high impact resistance, thermal stability, and food safety. I select each one based on the shell’s function and appearance.

How does injection molding improve durability?

Injection molding lets me control every detail. I achieve tight fits, low warpage, and strong bonds. This process creates shells that resist cracks, heat, and daily wear.

Why do I choose flame-retardant materials?

I choose flame-retardant materials to meet UL94 safety standards. These materials protect users from fire hazards and ensure the shell stays safe during use.

How do I ensure consistent quality in every shell?

I use automated sensors and strict inspections. My team checks each batch for defects. I track data to catch problems early and keep quality high.

Can I customize the look of my water dispenser shell?

Yes! I use in-mold decoration (IMD) and overmolding. These techniques let me add logos, textures, and colors that last.

Related Blog

Share