How Plastic Injection Molds Drive Innovation in Electrical Appliances

Release time:

Oct 03,2025

Key Takeaways

- Plastic injection molds offer design flexibility, allowing for complex shapes and integrated features that enhance appliance functionality.

- Using advanced materials and techniques, injection molding improves product durability and performance, leading to higher customer satisfaction.

- Efficient production processes reduce costs and time, enabling manufacturers to respond quickly to market demands and innovate faster.

- Texin's commitment to quality control ensures that every component meets strict standards, resulting in reliable and safe appliances.

- Sustainability is becoming essential in appliance manufacturing, with eco-friendly materials helping brands improve their image and reduce environmental impact.

Role of Plastic Injection Molds

Design Flexibility

You gain remarkable design flexibility when you use plastic injection molds in electrical appliances. This process allows you to create complex shapes and intricate internal structures that traditional manufacturing cannot achieve. You can integrate features like snap-fits, hinges, and ribs directly into the component, which streamlines assembly and boosts product reliability.

Tip: Design flexibility lets you respond quickly to market trends and customer preferences. You can update appliance aesthetics or add new functions without major changes to your production line.

Texin leverages injection molding to help you realize innovative design ideas. You can select from a wide range of thermoplastics and thermosetting plastics, each tailored for specific electrical, thermal, or mechanical properties. This flexibility means you can optimize your appliance for safety, durability, and visual appeal.

Here’s a table showing how injection molding enables design innovation in popular appliances:

You see that design flexibility is not just about shapes. It also covers the use of multiple materials and colors in a single mold. You can produce appliance parts with different textures, finishes, and even embedded electronics. In-mold electronics let you embed circuitry directly into the plastic, creating seamless and functional surfaces.

Advanced Features

Plastic injection molds drive innovation by enabling advanced features in electrical appliances. You can integrate complex geometries, conformal cooling channels, and functional elements that improve both performance and user experience.

- Injection molding produces parts with high precision and consistent dimensions. Your appliance components fit together perfectly, which leads to smooth and quiet operation.

- You benefit from enhanced cooling solutions. Conformal cooling channels, made possible by injection molding, help manage heat in devices like coffee machines and food processors.

- You can use materials like nylon for excellent electrical insulation. This is critical for connectors and circuit board housings, where safety matters most.

Texin’s expertise ensures that your innovative design ideas become reality. You get components with integrated features, such as snap-fits and hinges, that simplify assembly and boost durability. You also enjoy the ability to create complex internal structures, which traditional methods cannot match.

Here’s a table summarizing the design possibilities enabled by injection molding:

You also see efficiency gains. Injection molding allows for rapid production of high volumes of complex parts without sacrificing quality. Automation further boosts productivity and reduces costs. You can meet tight production schedules and bring innovative products to market faster.

- Injection molding supports the creation of complex structures and innovative designs.

- You achieve functional integration in appliance products, balancing aesthetics and usability.

- High-quality parts contribute to increased brand recognition and customer satisfaction.

Texin’s commitment to design innovation and engineering excellence helps you stay ahead in the competitive appliance market. You can rely on Texin to deliver molds that support advanced features, durability, and a premium finish.

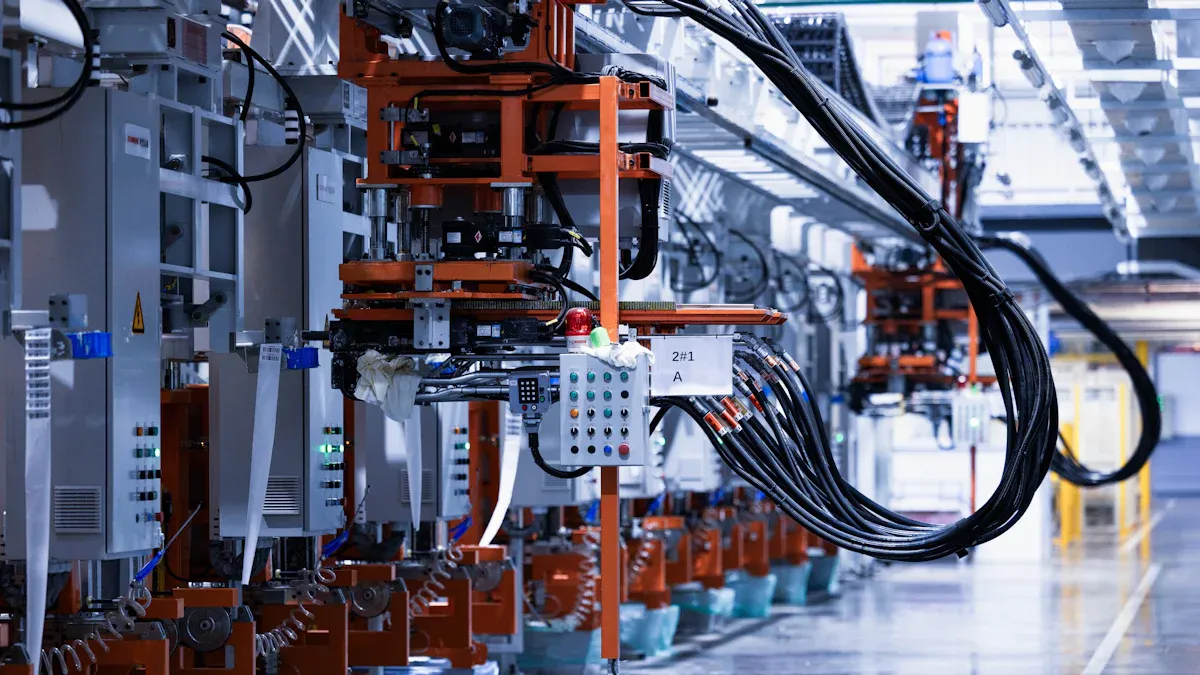

Injection Molding in Appliance Manufacturing

Efficiency Gains

You experience significant efficiency gains when you use injection molding in appliance manufacturing. This process eliminates many separate assembly steps, which streamlines production and reduces labor costs. You see improved product quality because injection molding allows you to create complex parts in a single operation. Texin’s advanced molding solutions help you incorporate secondary operations, such as labeling or inserting metal components, directly into the molding machine. This integration opens new opportunities for you to innovate and save time.

Energy-efficient practices in injection molding also contribute to substantial cost savings. All-electric injection molding machines enhance precision and efficiency, which leads to better material utilization and lower costs per part. You benefit from optimized processes that reduce waste and energy consumption. Effective quality control measures, such as real-time monitoring and regular inspections, minimize defects and the need for reprocessing. These steps ensure your products meet specifications and help you avoid unnecessary expenses.

- You eliminate separate assembly processes, which boosts efficiency.

- Manufacturing costs decrease due to streamlined operations.

- Quality improves with fewer defects and better consistency.

- Incorporating secondary operations into the molding process creates new possibilities for innovation.

- Energy-saving practices and advanced machinery lower operational costs.

Tip: When you optimize your injection molding process, you not only save money but also improve your production speed and product reliability.

Scalability

Injection molding supports scalability in appliance manufacturing. You can quickly produce large quantities of parts to meet market demand. Automated production lines enhance efficiency and reduce lead times, so you deliver products faster. Texin’s precision mold construction ensures accurate control of part sizes, which guarantees perfect matching with other components.

“Injection mold construction manufacturing technology can accurately control the size of parts, ensure their perfect matching with other components, thus improving the overall quality and performance of household appliances.”

The following table highlights how injection molding supports mass production while maintaining quality:

You benefit from quick production cycles and a steady supply of components. This scalability allows you to respond to changes in consumer demand and launch new products with confidence. Texin’s expertise in high-volume manufacturing ensures you maintain consistent quality, even as you scale up production.

Applications in Home Appliances

Kitchen Appliances

You interact with kitchen appliances every day. Plastic injection molds help create many parts for these devices. You see them in fridge components, such as holders and storage jars. Toaster parts and blender containers also use this technology. Dishwashers rely on injection-molded racks and internal parts. Texin uses advanced mold design to produce thin walls and integrated features, which make your appliances lighter and more durable.

You notice that painting or coating adds color and texture to appliance parts. Protective finishes resist UV radiation and wear. These features improve the durability and appearance of your home appliances.

Control Panels

Control panels play a key role in the functionality of modern appliances. You use them to operate devices like ovens, washing machines, and air conditioners. Plastic injection molds allow Texin to create panels with precise shapes and integrated buttons. This process supports cost-effective production and design flexibility.

Texin uses techniques like overmolding and insert molding to embed sensors and displays directly into control panels. You benefit from appliances with smarter features and improved reliability.

Connectors

Connectors link different parts of your appliances. You depend on their reliability for safe operation. Plastic injection molds enable Texin to manufacture connectors with high precision and consistent quality. You get cost-efficient and versatile connectors that fit many home applications.

- Precision manufacturing ensures accurate and reliable connectors.

- Cost efficiency lowers the price of large-scale production.

- Design flexibility allows for complex shapes and integrated features.

Texin follows a six-stage workflow to ensure connector reliability and safety. You see the results in appliances that work smoothly and last longer in your home.

Texin’s Approach to Injection Molding

Engineering Excellence

You expect high standards when you choose a partner for injection molding. Texin delivers engineering excellence by focusing on quality, efficiency, and precision. You benefit from years of experience in mold design and manufacturing. Texin’s team understands the challenges of creating electrical appliance components that require tight tolerances and flawless finishes.

Here is a table that shows what sets Texin apart in the industry:

Texin’s focus on precision ensures that every part meets strict requirements. You see the results in enhanced product performance and long-lasting durability. The company’s dedication to design innovation means you get solutions that improve both the look and functionality of your appliances.

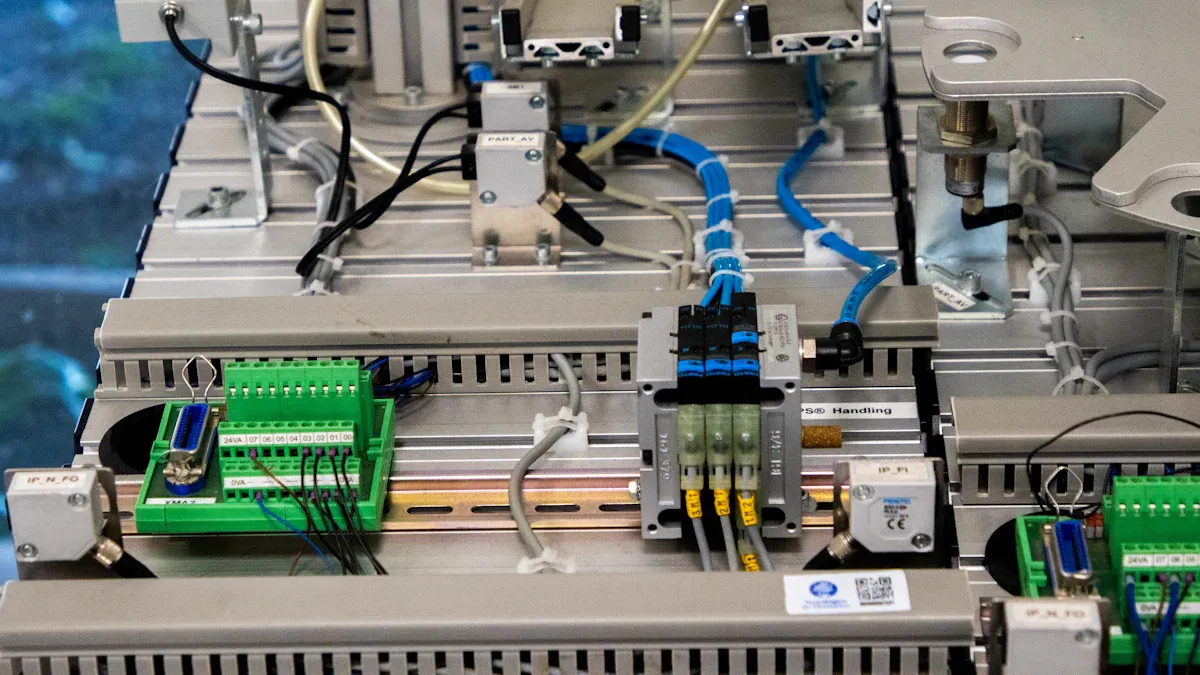

Workflow Stages

You want a process that guarantees quality and precision at every step. Texin uses a six-stage workflow that covers all aspects of injection molding for electrical appliances. Each stage adds value and reduces the risk of errors.

Here is how Texin’s workflow supports your project:

You start with a feasibility review. Texin’s engineers study your 3D models and key dimensions. They identify any design issues early, which prevents costly changes later. During mold design, you receive feedback that helps you achieve the best possible precision and manufacturability.

Texin procures high-quality materials that match your durability and performance needs. The precision machining stage uses advanced CNC and EDM equipment. This technology gives you micron-level accuracy and smooth finishes. During assembly, Texin checks every component for correct fit and function. Trial molding allows for final adjustments, so you get parts that meet your exact specifications.

You stay informed throughout the process. Texin provides weekly progress reports with photos during machining. You receive a qualification package that includes T1 samples, a dimensional report, and a molding process sheet. This transparency ensures your product meets all quality standards.

Material Selection

You need the right materials to achieve both durability and precision in your appliance components. Texin helps you select from a range of high-quality steels and plastics. The choice depends on your production volume, cosmetic requirements, and budget.

Texin uses different steels for different needs. For low-volume production, you might choose 45# steel. For high-polish surfaces or parts that require extra corrosion resistance, you can select S136 or NAK80. Texin’s experts guide you through the options, so you get the best balance of cost and performance.

You also benefit from Texin’s design innovation. The team helps you choose plastics that offer electrical insulation, heat resistance, or special finishes. This careful material selection supports enhanced product performance and long-term durability.

Tip: When you work with Texin, you get tailored solutions that match your unique requirements. The team collaborates with you from the first design review to the final product, ensuring every detail meets your expectations.

Texin’s approach to injection molding combines precision molding, expert material selection, and a customer-focused workflow. You receive parts that deliver outstanding functionality, durability, and visual appeal.

Quality Control in Appliance Manufacturing

Inspection Protocols

You want every appliance to meet the highest standards for safety and performance. Texin uses a rigorous inspection process at every stage of appliance manufacturing. You see quality checks during feasibility studies, mold design, machining, and final assembly. This approach ensures that each part meets strict requirements for precision molding and durability.

Texin’s team inspects molds for dimensional accuracy and surface finish. They use advanced measuring tools to check critical dimensions. You receive detailed reports with every batch, so you know your products meet industry standards. Texin also provides compliance support, including MSDS and RoHS declarations, to guarantee safety features and regulatory approval.

Note: Consistent inspection at multiple stages helps you avoid costly delays and ensures your appliances reach the market on time.

Avoiding Common Defects

You want your appliances to look great and work reliably. Texin addresses common defects in plastic injection molding by using advanced techniques and high-quality materials. You benefit from food-safe, heat-resistant, and low-warp products that perform well in daily use.

Here is a table showing some common defects and their causes:

Texin uses precision molding and advanced materials like PC, ABS, and PBT/PET+GF to prevent these issues. You see fewer sink marks, less warping, and improved safety in your finished products. The team also applies techniques such as IMD/IML decoration to enhance both appearance and durability. By focusing on quality at every step, Texin helps you deliver appliances with reliable safety features and long-lasting performance.

Future Trends in Injection Molding for Appliances

Smart Manufacturing

You see smart manufacturing changing the future of home appliances. Automation and digital technologies now shape how you design and produce appliance parts. You use real-time data to monitor machines and predict maintenance needs. This approach helps you improve operational efficiency and product quality. You can optimize production parameters with data analytics, which leads to fewer errors and faster cycles.

Here is a table showing key trends in smart manufacturing:

You benefit from integrating IoT devices for instant feedback. Predictive maintenance helps you minimize downtime. Texin uses these smart systems to deliver precise injection molding and reliable appliance components.

Sustainable Materials

You recognize sustainability as a driving force in appliance manufacturing. You choose eco-friendly materials to reduce your carbon footprint and support environmental benefits. Renewable and recycled plastics help you conserve resources and keep plastic waste out of landfills and oceans. You see efficient resource management through reduced water usage and responsible chemical handling.

Here is a table highlighting the impact of sustainable materials:

You notice that sustainable practices improve your brand image. Consumers want appliances made with eco-friendly materials. You gain market share by focusing on sustainability and environmental benefits. Texin supports you by offering advanced design solutions that use sustainable materials.

Industry Leadership

You look for leaders who shape the future of home appliances. Texin stands out by embracing sustainability and innovation. You benefit from enhanced precision, as electronic controls allow tighter tolerances and reduce secondary operations. Real-time data analysis gives you instant feedback, so you can adjust production quickly.

Texin’s optimized processes consume less energy and reduce material waste. You see sustainability in every step. The company adopts Industry 4.0 principles, including IoT and AI, to advance injection molding capabilities. You trust Texin to guide you toward the future of home appliances with sustainable practices and cutting-edge design.

Tip: When you choose Texin, you invest in sustainability, environmental benefits, and the future of home appliances.

You see how plastic injection molds drive innovation in appliances. You rely on precision to create advanced features for home appliances. Texin helps you achieve reliable appliance performance and attractive finishes for your home. You benefit from Texin’s leadership in precision and customer collaboration. You can expect injection molding to shape the future of home appliances with new levels of precision and design possibilities.

Texin supports your journey toward smarter, more efficient appliance solutions for every home.

FAQ

What types of appliances benefit most from plastic injection molding?

You see the biggest impact in kitchen devices, vacuum parts, control panels, and connectors. Texin’s molds help you achieve precise, durable, and attractive components for these products.

How does Texin ensure the quality of each mold?

Texin uses strict inspection protocols at every stage. You receive detailed reports and samples. This process ensures your molds meet high standards for accuracy and durability.

Can Texin help with custom designs or unique features?

You can work with Texin’s engineers to create custom molds. The team reviews your 3D models and requirements, then develops solutions tailored to your appliance’s needs.

What materials does Texin use for injection molds?

You choose the material that fits your project best.

Related Blog

Share