Why Plastic Injection Molds Matter for Fast Auto Production in 2025

Release time:

Oct 02,2025

You want fast, reliable auto production in 2025. High precision plastic injection molds drive this change. Texin leads with advanced materials and precision engineering, giving you a clear advantage.

- The injection molding segment is set to lead the market, using lightweight, sustainable materials and smart manufacturing for better quality and efficiency.

Key Takeaways

- Texin's high-precision plastic injection molds enable fast and reliable automotive production, helping you meet tight deadlines.

- Using advanced materials and micron-level accuracy, Texin molds reduce defects and downtime, leading to shorter cycle times and higher efficiency.

- The flexibility of Texin's molds allows for the production of complex designs, ensuring you can adapt quickly to changing market demands.

Speed and Efficiency

Plastic Injection Molds for Fast Production

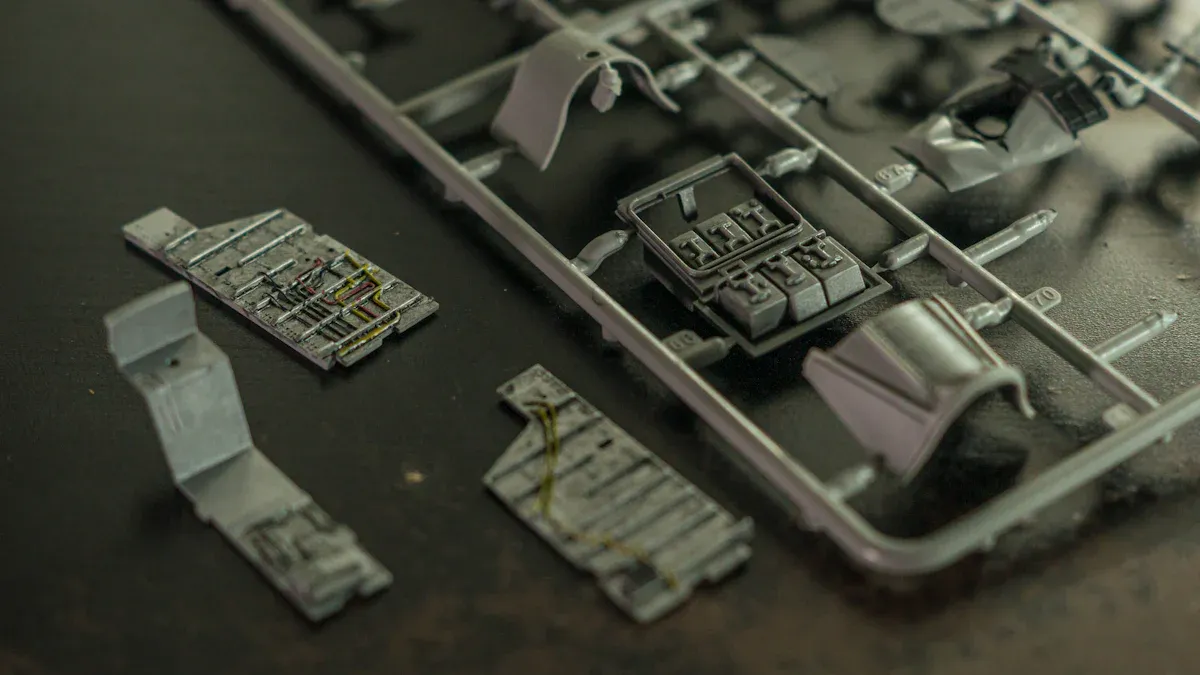

You need fast and reliable manufacturing to stay ahead in the automotive industry. Plastic injection molds play a key role in making this possible. When you use Texin’s high-precision molds, you can achieve rapid mass production for a wide range of automotive components. These molds support high-volume production, so you can meet tight deadlines and deliver consistent results.

Texin’s process starts with fast feasibility checks. You get feedback on your design in just 1 to 3 days. This quick response helps you avoid delays and move forward with confidence. Once your design is ready, Texin uses advanced CNC and EDM machining to create molds with micron-level accuracy. This level of precision means your molds produce parts that fit perfectly every time.

Tip: Fast feasibility checks and precise machining help you catch design issues early, saving you time and money during production.

Plastic injection molding allows you to manufacture complex shapes and detailed features in a single step. You can reduce the number of assembly operations and speed up your workflow. With Texin’s expertise, you can trust that each mold will deliver the consistency and quality you need for automotive applications.

Reduced Cycle Times

You want to maximize efficiency and minimize downtime on your production line. Texin’s injection molding solutions help you achieve both. High-precision molds reduce the risk of defects, so you spend less time on rework and quality checks. This leads to shorter cycle times and higher throughput.

Micron-level accuracy in mold machining ensures that each part meets strict dimensional standards. When your molds control tolerances at the micron level, you avoid problems like burrs or deformation. This precision keeps your production running smoothly and helps you maintain high safety and reliability standards.

- How Texin’s molds boost your efficiency:

- Fast feasibility checks identify risks early.

- Micron-level machining delivers consistent, high-quality parts.

- Durable materials like 45#, 718H, S136, and NAK80 extend mold life.

- Optimized mold design reduces cycle times and increases output.

Plastic injection molding supports high-volume production with minimal interruptions. You can rely on Texin’s molds to handle the demands of automotive manufacturing, from interior trims to under-the-hood brackets. This approach not only improves efficiency but also lowers operational costs by reducing waste and downtime.

When you choose Texin, you invest in molds that keep your production line moving fast and efficiently. You gain a competitive edge in the automotive market by delivering quality parts on time, every time.

Quality and Reliability

Injection Molding Consistency

You expect every automotive part to meet strict standards. Texin delivers this through advanced materials and a proven workflow. When you choose Texin, you get molds built from materials like 45#, 718H, S136, and NAK80. These materials offer heat and corrosion resistance, which means your molds last longer and perform reliably in demanding environments.

Here is how these materials contribute to durability and safety:

You benefit from consistent quality in every production run. Texin’s plastic injection molding process uses these materials to ensure that each mold withstands high-volume production. You avoid frequent replacements and reduce downtime, which boosts your efficiency.

Note: Durable materials help you maintain safety and reliability for all automotive applications.

Texin’s commitment to quality control starts with material selection. You receive molds that meet the highest standards for automotive manufacturing. This attention to detail supports consistent quality and reliable performance.

Precision in Automotive Parts

You want high-quality parts that fit perfectly and function safely. Texin’s six-stage workflow ensures tight tolerances and uniform finishes. The process includes feasibility studies, mold design, material selection, precision machining, assembly, and trial runs. Each stage focuses on quality control measures that guarantee consistent quality.

Let’s look at how Texin’s molds compare to industry standards:

You gain confidence in every part produced. Texin’s injection molding process uses high precision machining to achieve micron-level accuracy. This means you get parts that meet strict dimensional requirements and pass all quality control checks. You avoid defects and rework, which saves you time and resources.

Texin’s workflow supports high-volume production without sacrificing quality. You receive molds designed for efficiency and reliability. The team at Texin monitors every step, applying quality control measures to maintain consistent quality. You see the results in the finished automotive components—each part meets your specifications and performs as expected.

Plastic injection molding with Texin gives you a competitive advantage. You get molds that deliver consistency, durability, and safety for all your manufacturing needs. You can trust Texin to support your production goals with high-quality parts and reliable service.

Cost and Benefits

Lower Waste with Precision

You want to reduce waste and improve efficiency in your manufacturing process. Texin’s plastic injection molds help you achieve this goal. Precision in injection molding means each part matches your design with minimal post-processing. You see less material wasted and fewer defects. This lowers your costs and keeps your production line running smoothly.

When you use high-precision molds, you avoid rework and save valuable resources. The manufacturing process becomes more efficient because you spend less time correcting errors. You also benefit from consistent quality in every batch. Texin’s molds support high-volume production, so you can meet demand without sacrificing quality.

Tip: Precision molds help you cut down on scrap and reduce the need for extra labor.

Benefits of Plastic Injection Molding

You measure the return on investment by looking at both upfront and ongoing costs. With Texin, you invest in molds designed for long service life. You pay for mold design and fabrication, but you save money over time through lower production costs and fewer repairs. The manufacturing process uses less material and energy, which boosts cost-effectiveness.

Here are the main factors you should consider:

- Initial investment covers mold design and engineering.

- Production costs include material, machine setup, and quality control.

- Ongoing maintenance involves cleaning and repairs.

- Potential returns come from reduced waste and the ability to offer high-quality products.

Texin’s solutions also support your sustainability goals. The materials used in injection molding help you lower carbon emissions and meet environmental standards. You align your manufacturing process with industry regulations and reduce your impact on the environment.

You gain cost savings, improved efficiency, and reliable quality for all your automotive applications.

Flexibility and Innovation

Complex Designs with Plastic Injection Molding

You need flexibility in your manufacturing process to keep up with changing automotive trends. Texin’s plastic injection molds give you the design flexibility to create both simple and complex parts. You can produce precision components that meet strict quality standards. With injection molding, you can achieve high-volume production of parts with intricate shapes and fine details.

Some of the complex automotive components you can manufacture with Texin’s injection molding technology include:

- Precision parts such as cams

- Gears for transmission systems

- Mechanical parts for moving assemblies

- Exterior applications that require both strength and aesthetics

Texin’s molds support a wide range of finishes. You can choose from textured surfaces for interior trims or mirror finishes for decorative parts. This level of customization ensures that each part fits your specific applications and meets your quality expectations.

Quick Adaptation to New Models

You want to respond quickly to new market demands. Texin’s injection molding process uses a full six-stage workflow that streamlines every step of production. Fast feasibility checks help you identify design risks in just a few days. You can make rapid adjustments and move forward with confidence.

Texin’s trial runs and validation steps let you test and refine your molds before full-scale production. You can adapt to new models and features without slowing down your manufacturing process. This approach supports rapid production cycles, high efficiency, and cost-effectiveness. You gain the benefits of consistency, customization, and reliable performance in every batch.

Competitive Edge

Benefits for 2025 Auto Makers

You want to stay ahead in the fast-changing automotive industry. Texin gives you that edge with plastic injection molds designed for high-volume production. You gain more than just tools; you get a partner who understands your needs. Texin’s transparency in the manufacturing process lets you track every step, from design to delivery. You see clear timelines and know exactly what to expect.

A skilled team supports you at every stage. You receive guidance on material selection and mold design. This support helps you avoid costly mistakes and keeps your production on schedule. Texin tailors solutions to fit your specific requirements. You can adapt quickly to new models or changes in demand. This flexibility boosts your efficiency and cost-effectiveness.

Note: Choosing Texin means you get reliable molds that help you meet strict quality standards and deliver consistent results.

Texin’s Industry Leadership

Texin leads the way in automotive manufacturing. You benefit from advanced expertise in the manufacturing process and mold engineering. Texin uses a proven six-stage workflow to ensure every mold meets your exact needs. You can trust the durability and precision of each mold, even during high-volume production.

Here is how Texin stands out:

You want a partner who values quality and innovation. Texin delivers both. Contact Texin today to discuss how high-precision molds can transform your manufacturing process and help you lead the market in 2025.

You gain a clear advantage with Texin’s plastic injection molds.

- You speed up production and reduce time-to-market.

- You achieve consistent quality and efficient use of resources.

- You create complex, modern designs with flexibility.

Choose Texin to future-proof your automotive production and stay ahead in 2025.

FAQ

What types of automotive parts can Texin molds produce?

Texin molds create interior trims, connectors, housings, and under-the-hood brackets. You can also request custom designs for unique automotive components.

How fast can Texin deliver a feasibility check?

You receive a feasibility check from Texin in just 1 to 3 days. This quick feedback helps you start your project sooner.

Why should you choose Texin for automotive injection molds?

You get high-precision molds, durable materials, and expert support. Texin helps you achieve reliable, efficient, and cost-effective auto production.

Related Blog

Share