3 Big Reasons Plastic Injection Molds Are Best for Containers

Release time:

Oct 01,2025

You need containers that deliver exact results every time. Plastic injection molds make this possible, dominating over 50% of global container manufacturing:

Texin brings you unmatched precision, efficiency, and cost savings. Industries like consumer goods, electronics, medical, and packaging trust plastic injection molding for reliable, high-volume production. Choose Texin for proven quality.

Key Takeaways

- Plastic injection molds provide fast and scalable production, allowing you to meet market demands quickly.

- You gain precise and consistent quality with every container, ensuring reliability for your products.

- Investing in plastic injection molds offers long-term cost savings through reduced waste and durable materials.

Precision & Consistency

Uniform Results

You want every container to look and perform exactly the same. Plastic injection molding gives you this reliability, making it the top choice for food, cosmetics, and medical packaging. Texin’s expertise ensures you get containers with consistent wall thickness and flawless surface finish. Their use of high-grade materials like 45#, 718H, S136, and NAK80 means your containers stay strong and durable, even under demanding conditions.

Texin’s advanced machining and strict process control guarantee repeatable results. You benefit from scientific molding methods that limit variation to just +/- 25 microns. Real-time monitoring and calibration keep every cycle precise. Here’s how the process delivers uniformity:

Tight Tolerances

Plastic injection molds excel at producing containers with tight tolerances. You get defect-free parts that meet strict safety and quality standards. Texin’s design review process focuses on preventing warpage, sink marks, and flow lines. Their team optimizes mold cooling channels and wall thickness, so your containers maintain their shape and integrity.

- Mold deflection is estimated up to 12 μm, keeping your containers precise.

- Uniform wall thickness and cooling channels minimize defects.

- Quality control measures catch issues before they reach you.

Texin’s commitment to precision means you receive containers that fit perfectly, seal securely, and protect your products. Choose Texin for plastic injection molding that delivers unmatched consistency and quality every time.

Efficient Plastic Injection Molding

Fast Production

You want your containers delivered quickly and reliably. Plastic injection molding gives you fast production, saving you time and resources. Texin’s process starts with a rapid feasibility review, completed in just 1-3 days. You get your mold design in 3-7 days, so your project moves forward without delay. This speed means you can respond to market changes and customer demands faster than ever.

Texin’s advanced molding technology supports high efficiency and minimal downtime. You benefit from automated production lines and streamlined workflows. Your containers reach the market quickly, giving you a competitive edge.

Scalable Output

Plastic injection molding lets you scale up your production with ease. You can produce thousands or even millions of containers using high-volume injection molding. Texin’s multi-cavity molds allow mass production in every cycle, adapting to your needs as demand grows.

Plastic injection molding combines high efficiency with excellent precision, making it ideal for large-scale production.

- Speed

- Consistency

- Scalability

- Low Labor Costs

- Cost Savings

- High-Precision Dimensional Tolerances

- Low Unit Costs and Cycle Times

- Automated Production

- Minimal Post-Production Work

- Versatile Material Options

- Flexibility in Design

High-volume injection molding achieves scalability through multi-cavity molds. You get consistent quality, whether you need custom plastic enclosures or standard containers. Texin’s molds endure thousands to millions of cycles, so you enjoy reliable output and long-term value.

Texin’s expertise in plastic injection molds ensures your production stays efficient, scalable, and cost-effective. Choose Texin for your next molding project and experience the benefits of high-volume, high-quality container manufacturing.

Cost-Effective Plastic Injection Molds

Material Savings

You want to maximize every dollar spent on container production. Plastic injection molding helps you achieve this by minimizing waste and lowering costs. Texin’s process uses hot runner molds that keep plastic molten, eliminating excess material in runners. You benefit from closed-loop recycling systems that collect and reuse scrap, reducing both waste and production costs. Design optimizations, such as thin-wall molding, let you use less plastic without sacrificing strength. This approach supports sustainability and environmental sustainability, making your operation greener.

You can choose from a wide range of materials, including polypropylene, ABS, and PE. These options offer cost-effective benefit and durability, helping you save on raw material costs. Texin’s expertise in molding ensures you get plastic injection molded parts that meet your needs for custom and flexible designs.

Long-Term Value

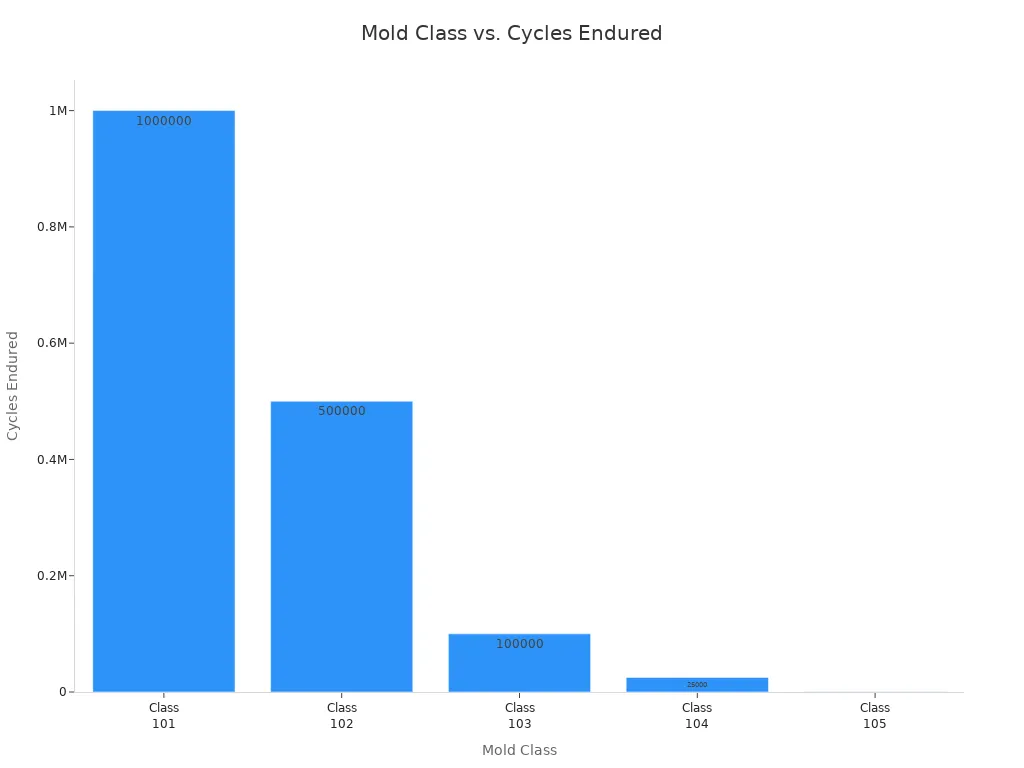

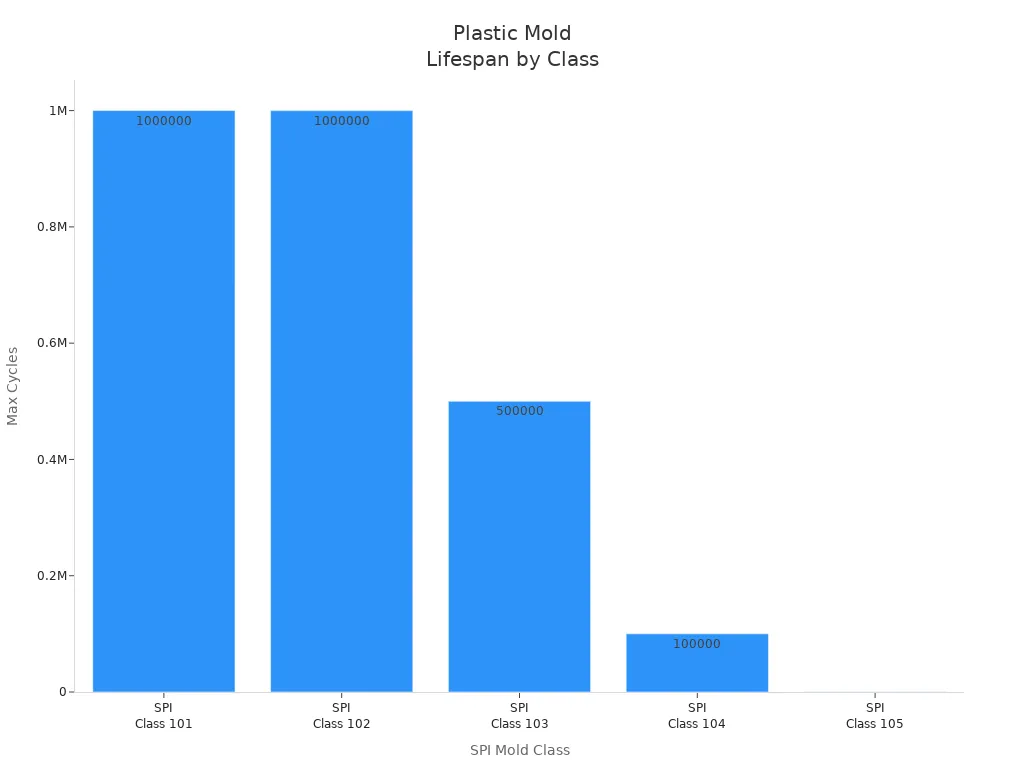

Investing in plastic injection molds gives you lasting value. Texin’s molds are built for longevity, with SPI Class 101 molds enduring over one million cycles. This durability means you spend less on replacements and repairs. The chart below shows the cycle range for different mold classes:

You receive realistic cost and schedule planning from Texin, so you avoid surprises. Their after-sales support includes a one-year warranty, remote guidance, and spare parts supply. Free replacement is available if the fault is on Texin’s side. Maintenance services, such as regular cleaning, lubrication, and inspection, extend mold life and performance.

Surface finish options add even more value. You can select from leather grains, graphics, geometrics, or custom etching. These finishes improve aesthetics, functionality, and durability, making your containers stand out. Texin’s molding process delivers plastic enclosures and containers with flexible designs that support your brand and sustainability goals.

You gain three key advantages with plastic injection molds:

- Fast, scalable production

- Precise, consistent quality

- Long-term cost savings

Choose Texin and lead the way in efficient, sustainable container manufacturing.

FAQ

What types of containers can you produce with plastic injection molds?

You can create food jars, cosmetic bottles, medical vials, and industrial drums. Texin customizes molds for your specific container needs.

How long do Texin molds last?

You get molds that last for thousands to millions of cycles. Texin uses high-grade materials for maximum durability and value.

Can Texin help with custom designs?

Absolutely! Texin works with you to develop custom container molds. You receive expert guidance from concept to final production.

Related Blog

Share